Selling only

in Canada

FAQ - Pallets boxes

It is a large container on a pallet. The walls and bottom of the container can be solid or vented. Some models such as fixed-wall pallet boxes are moulded in one piece, while other models are composed of several parts assembled together like 4 removable or folding walls or like a box screwed on a pallet with specialized hardware.

The walls of the container are straight, meaning that the base is the same dimension as the top which allows stacking the bins on each other. Stacking can be done with or without the lid, in both situations the piles are stable and safe thanks to the interlocking corners. Since the walls support the load, several units can be stacked without any problems, saving storage space and optimizing transport.

The walls of the pallet box are oblique, meaning that the base is smaller than the top which allows the bins to enter into each other. They save space in the warehouse and reduce transport costs. These pallet boxes require a lid to be stacked. The stacking is restricted because it is the lid that supports the load and not the walls of the box, so a maximum of 2 units stacked in motion, but 3 units stacked in static storage. This type of crate is watertight, but it is not recommended for liquid because the walls can swell and the lid won’t fit anymore.

It is a pallet box with 4 walls completely detachable from the pallet. It offers the possibility of removing a wall to allow loading or unloading with a forklift or simply to facilitate access to its content. It is possible to obtain a higher bin by attaching one or two additional sets of walls to the current walls using clips. A panel can then be flipped to create an access door. They are available with solid and vented walls and this type of box is not waterproof, so no liquid can be stored in it.

It is a pallet box with 4 folding walls. This concept makes it possible to reduce the height of the unused bin, thereby saving space and reducing the cost of transport. The 2 long sides have a hinged access door making it easy to reach the content. They are ideal for optimizing handling and bulk storage. They all have solid walls, but depending on the model, the base can be vented or solid. Even with a solid base, this type of pallet box is not waterproof, so no liquid can be stored in it.

It is a pallet box with double walls filled with an insulating polyurethane. Its double-wall design makes it a sturdy box that makes it easy to handle, transport and store bulk of fresh or frozen food. They are ideal for ice conservation. A drain moulded in the box allows the drainage of liquids. This type of pallet box is mainly used in fisheries and in food plans. The pallet boxes are waterproof and the lid has rubber straps to securely hold it in place to secure the contents. They work fine for any type of solid or liquid content.

Walls and bases are made of a single wall. It ca be solid or vented.

It is a pallet box with a double wall thickness, the cavity between the two walls is filled with polyurethane foam, which gives much more structure and strength, also offering insulating properties. If the walls are pierced, liquid can be inserted between the two walls and penetrated into the airspace of the polyurethane. The bin will no longer be considered food grade.

It is a pallet box which has a double thickness of walls and the cavity between the two walls is filled with a polyethylene foam so dense that even a liquid cannot penetrate this material. This foam is considerate as the triple wall. Triple-wall pallet boxes are highly impact resistant and have a very long service life. Even if they are pierced, no liquid can be inserted into the polyethylene foam. The whole can be dried and be repaired by welding, so the bin can be reused without any problems.

Models with fixed and solid walls are waterproof and may contain liquids. However, pallet boxes with folding or removable walls, or with vented walls are not designed for liquids. Depending on the model, they can be filled from 50% to 100% of their available volume without the walls swelling under the pressure of the liquid. Some pallet boxes have a drain, while other models offer it as an option.

The answer is mainly no, but it depends on the type of racking used. In general, all pallet boxes are designed to be used on the ground, so that their base is fully supported to distribute the load evenly. They are not made to be supported only on security bars in a racking system. On the other hand, if you add mesh wire or plywood sheets in your racking system and completely cover the steel bars, then the load of the pallet box will be scattered and this will allow you to store them in rack.

All pallet boxes are made of polyethylene (PE). This is the most common type of plastic for the manufacture of this type of container. It is a temperature and impact-resistant material, it is suitable for all types of moulding processes such as rotational mouldings, injection moulding or injection moulding with structured foam. Virgin polyethylene is often presented in different colours and complies with food standards. Recycled polyethylene is normally presented in black and is not food grade.

Most of the pallet boxes we offer comply with FDA or CFIA standards for direct contact with food because they are made from virgin polyethylene in which food colouring has been added. Only black foldable pallet boxes are made from recycled polyethylene, therefore they are not food grade.

Yes, it is possible to add a drain on most models of single-walled pallet boxes. However, it is not possible to add one on double and triple wall pallet boxes that do not include one, because the drain is moulded during the manufacture of the box only.

Yes, it is possible to banish the drain installed by the manufacturer, but in most cases single wall pallet boxes come without a drain and should be added if needed. For those with double or triple walls, the drain is moulded in the box during manufacture, because it is not possible to add one later, but it is possible to order a pallet box without drain.

It depends on the kind of breakage. It is possible to weld the plastic to repair a small hole, a crack or to join two pieces together. We can also change broken parts like a hinge, for example. But if a panel is torn off or a leg is missing, the breakage is too major to repair. It is better to change the pallet box and it is recyclable.

The pallet boxes are all made of polyethylene which is a material that withstands temperatures ranging from -28 °C to 49 °C / -18 °F to 120 °F

Absolutely. The material that composes them is not affected by soaps and chemicals, so they can be cleaned with steam, with the pressure washer or in an industrial washing machine. The washing water must not exceed 49 °C / 120 °F.

No, the lid is not mandatory if the contents do not need to be covered. However, only oblique-wall pallet boxes must be used with the cover for stacking, because the base being smaller than the top, it is the cover that supports the load and not the walls. On the other hand, all pallet boxes with straight walls can be stacked on top of one another with or without the lid.

Yes. The properties of the plastic vary according to the type of moulding.

The pallet boxes designed by the injection moulding process have simple walls, they can be moulded in large quantities of uniform thickness and have a high durability. They have a good load capacity. Their surface is smooth and easy to maintain.

Pallet boxes designed by the injection moulding process and structured foam have single walls, allowing greater load capacity, because the plastic is stiffer and a little stronger. However, it is a little less resistant to low temperatures because it is more brittle. This process makes it possible to mould in large quantities and of uniform thickness. Their surface is less smooth, but still easy to maintain.

The pallet boxes manufactured by the rotational moulding process may have single, double or triple walls. This method does not allow to manufacture large quantities at a time and the thickness of the walls can be variable. The pallet boxes are very resistant to shocks because the plastic is more flexible and absorbs impacts well. The surface is very smooth, easy to clean and can have different finishes.

The leg base normally contains 9 moulded legs and this design allows you to enter the forks of a pallet truck or forklift on all 4 sides without obstruction. The runners connect the legs together and give more support to the body. A forklift is normally used on the side of the runners. They also allow to retain the pallet box when it is tilted on rotating forks. There are models of pallet boxes with bases that have 2 or 3 runners installed using clips or directly moulded to the pallet box.

By their weight, it is difficult to handle them by hand, so a pallet truck, a forklift or even rotating forks are the most commonly used equipment to handle this kind of equipment.

It depends on the pallet box model. The ideal is to refer to the detailed product page to obtain this information. In general, we limit the number of units to 2 or 3 high when in dynamic mode and depending on the model, from 3 to 10 in static mode.

Call an expert

Did not find the information you were looking for?

Ask us your question directly!

Need assistance? Contact us at 450 471-2772

Français

Français  English

English

Vertical Closed Top Storage Tanks

Vertical Closed Top Storage Tanks  Free Standing Horizontal Tanks

Free Standing Horizontal Tanks  Rectangular Utility Tanks

Rectangular Utility Tanks  1000 Litre IBC Tanks (Cage Tote)

1000 Litre IBC Tanks (Cage Tote)  Vertical Open Top Storage Tanks

Vertical Open Top Storage Tanks  Double Wall Tanks

Double Wall Tanks  Plastic Water Stock Tank

Plastic Water Stock Tank  Rectangular Open Top Tanks

Rectangular Open Top Tanks  Cone Bottom Tanks - Closed Top Plastic Tanks

Cone Bottom Tanks - Closed Top Plastic Tanks  Cone Bottom Tanks - Open Top Plastic Tanks

Cone Bottom Tanks - Open Top Plastic Tanks  Pick up Tanks

Pick up Tanks  Secondary containment basins

Secondary containment basins  Cage Tank Parts (IBC Tote)

Cage Tank Parts (IBC Tote)  Polypropylene and PVC Ball Valves

Polypropylene and PVC Ball Valves  Polypropylene and PVC Tank Fittings

Polypropylene and PVC Tank Fittings  Camlock Fittings

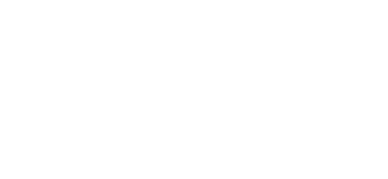

Camlock Fittings  Stainless Steel Bolted Fitting

Stainless Steel Bolted Fitting  Polypropylene Threaded Reducer Nipples

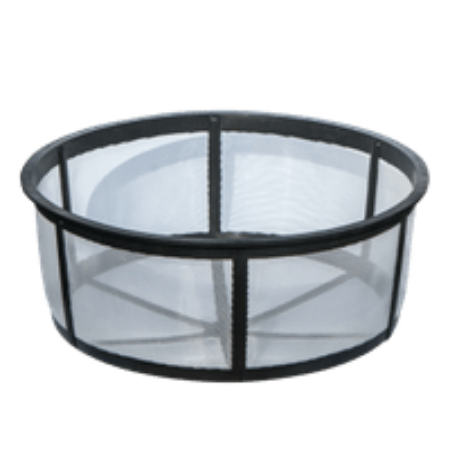

Polypropylene Threaded Reducer Nipples  Polypropylene Threaded Reducer Bushings

Polypropylene Threaded Reducer Bushings  Hose Barb Fitting Adapter

Hose Barb Fitting Adapter  Vent Caps

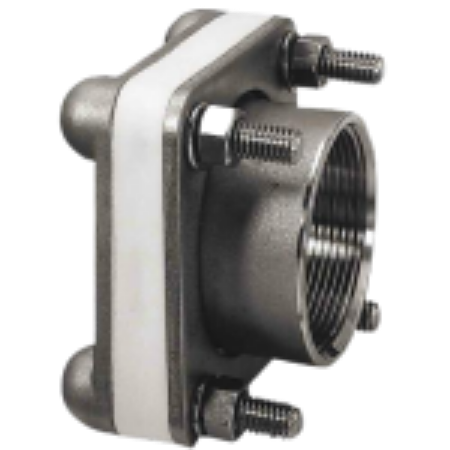

Vent Caps  Filter Strainer Basket

Filter Strainer Basket  Threaded Pipe Nipples

Threaded Pipe Nipples  Polypropylene Tee Fitting, NPT Female Thread

Polypropylene Tee Fitting, NPT Female Thread  Polypropylene Cross Fitting, NPT Female Thread

Polypropylene Cross Fitting, NPT Female Thread  Drain Plugs

Drain Plugs  Elbow fittings

Elbow fittings  PVC Adapter, NPT Male Thread to Socket End

PVC Adapter, NPT Male Thread to Socket End  Polypropylene Threaded Pipe Couplings

Polypropylene Threaded Pipe Couplings  Closed Top Tank Lids

Closed Top Tank Lids  Fire Hydrant Adapters for Quebec

Fire Hydrant Adapters for Quebec  Level Indicator

Level Indicator  Miscellaneous accessories

Miscellaneous accessories  Potable Water Hoses

Potable Water Hoses  Liquid Suction and Discharge Hoses

Liquid Suction and Discharge Hoses  Liquid Discharge Hoses

Liquid Discharge Hoses  Fire Hose

Fire Hose  Hose Clamps

Hose Clamps  Plastic Containers, Solid Walls and Bottom

Plastic Containers, Solid Walls and Bottom  Plastic Containers, Vented Walls and Bottom

Plastic Containers, Vented Walls and Bottom  Attached Lids Plastic Containers

Attached Lids Plastic Containers  CS Plastic Totes with Mobile Shelving

CS Plastic Totes with Mobile Shelving  "Brute" Round Containers

"Brute" Round Containers  Sand and Salt Plastic Storage Bins

Sand and Salt Plastic Storage Bins  Large Volume Plastic Tubs

Large Volume Plastic Tubs  Containers Options and Accessories

Containers Options and Accessories  FDA Food Grade Plastic Pallets

FDA Food Grade Plastic Pallets  Industrial Plastic Pallets for Warehouse and Racking

Industrial Plastic Pallets for Warehouse and Racking  Drum Plastic Pallets

Drum Plastic Pallets  Plastic Pallet Boxes, Solid walls and Bottom

Plastic Pallet Boxes, Solid walls and Bottom  Plastic Pallet Boxes, Vented walls and Bottom

Plastic Pallet Boxes, Vented walls and Bottom  Insulated Plastic Pallet Boxes

Insulated Plastic Pallet Boxes  Folding-wall Pallet Boxes

Folding-wall Pallet Boxes  Pallet Boxes on Casters

Pallet Boxes on Casters  Pallet Boxes Options and Accessories

Pallet Boxes Options and Accessories  Custom Plastic Pallet Boxes

Custom Plastic Pallet Boxes  Food Grade Buggies / CFIA - FDA Carts

Food Grade Buggies / CFIA - FDA Carts  Industrial Poly-Box Trucks

Industrial Poly-Box Trucks  Plastic-Shelf Utility Carts

Plastic-Shelf Utility Carts  Carts Options and Accessories

Carts Options and Accessories  Hygienic Shovels

Hygienic Shovels