Plastic welding and custom modifications of plastic pallet boxes and plastic tanks in Quebec

Plastic pallet box modifications: adding access doors, casters and custom size adjustments

Plastic tank modifications: welded flanges, fittings, lifting lugs, anchor legs and pump supports

We are here to make it happen!

We leverage our experience and expertise to bring all your projects to life, regardless of their nature. In close collaboration with our manufacturers and specialized partners, we are able to assist you in modifying pallet boxes or plastic tanks to adapt existing products to your specific needs.

Do you need precise dimensions for a pallet box? Do you want to integrate an anchoring or anti-seismic system into a tank? Does your assembly require specific welded flanges and connections? We are able to meet these requirements while adhering to your industry's standards.

- To adapt a pallet box to specific requirements, we can make modifications such as adding casters for increased maneuverability, installing an access door for better accessibility and we can even modify one of its dimensions such as height, width or length.

- Only MX and Dolav series pallet boxes can be personalized

- Consult our section dedicated to Custom Plastic Pallet Boxes

- To obtain an evaluation of your project, contact us by email or by phone at 450-471-2772 Ext. 1

- On plastic tanks, we can weld flanges, connection fittings, a shelf to hold equipment, lifting rings, anchor brackets or even a pump support, directly welded to the tank wall

- For more information on plastic tanks, see the Plastic Tanks section

- To obtain an evaluation of your project, contac us by email or by phone at 450-471-2772 Ext. 1

- You can print the technical drawing of the tank from the product detailed page.

Our commitment to our customers continually pushes us to find the best ways to offer advanced expertise in the field of plastic welding, allowing us to guarantee high-quality tailor-made solutions, perfectly adapted to your specific needs. Visit our Accompanying Service section to learn more about our expertise and services. Do not hesitate to contact us to discuss your personalized projects. We look forward to collaborating with you to bring your most ambitious ideas to life.

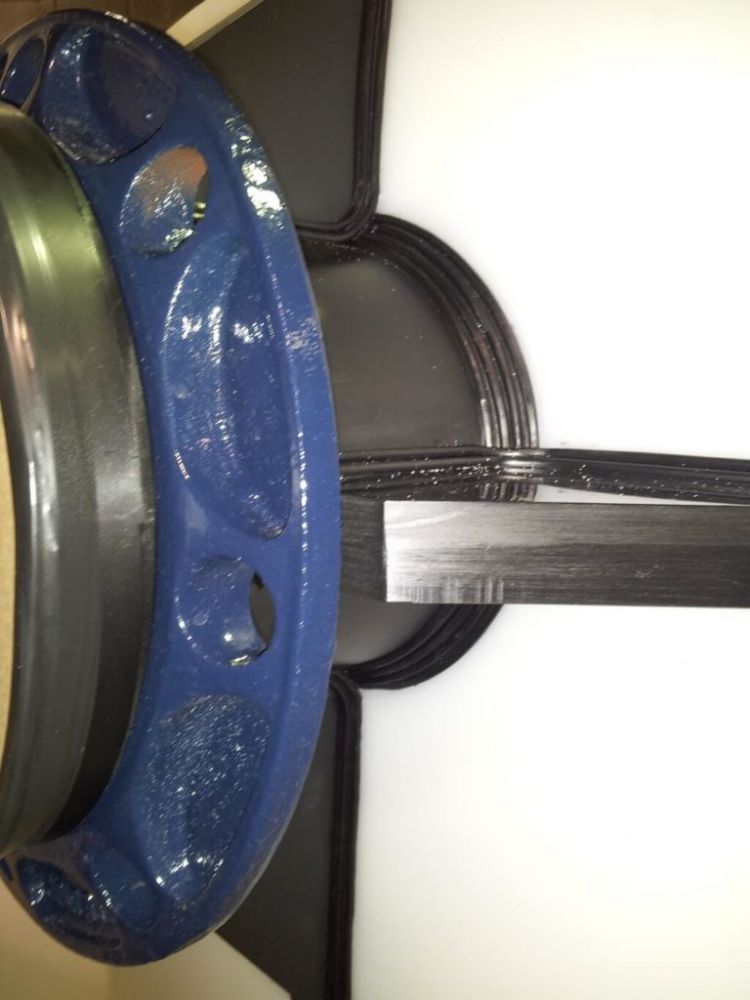

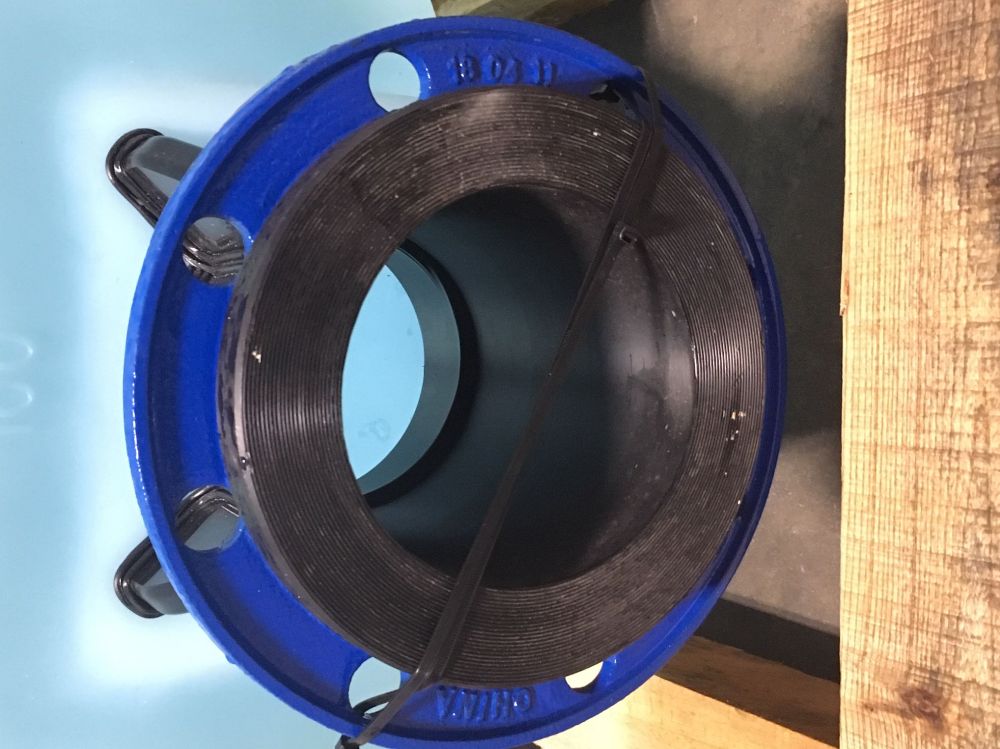

6″ Welded HDPE Flanges and 1″ Sight Glass Level Indicator

– 6″ black polyethylene (HDPE) pipe, DR17.

– 4 black HDPE brackets cut and welded around the pipe to support the flange.

– Blue painted metal flanges with EPDM gaskets, class # 150.

– 1″ clear PVC level indicator tube fixed with 1″ welded half couplings.

– This assembly was performed on a 525 US gallons horizontal tank of 1.9 density.

For this assembly, the customer drew on the technical drawing of the tank, all the accessories that were needed to be installed, by specifying the location and the diameter of each one. The project was a transport tank equipped with four 6″ welded flanges and a sight glass level indicator, that could be moved from one site to another. For proper flange welding installation, a 1.9 density, with thicker walls, tank was used. Since frost settles on the wall due to the rather cold operating temperature, a 1″ external level indicator has been installed on the front of the tank. It comes with 90° PVC elbows and PVC/EPDM isolation ball valves, to cut the leak in case the tube is broken. Due to the curves in the tank walls, two 1” welded connections were installed to hold the gauge in place.

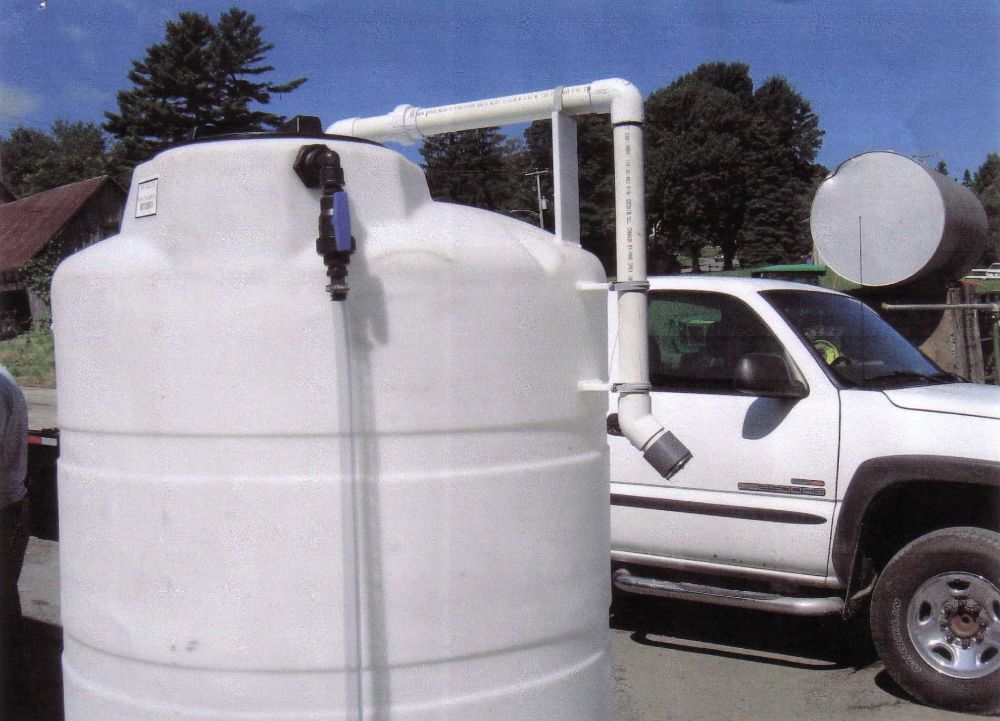

2″ Inner/Exterior PVC Pipe For Filling and 1″ Sight Glass Level Indicator

– 2″ PVC external pipes for filling, with welded HDPE fastening brackets.

– 2″ PVC internal pipes to prevent spatter and foam.

– 1″ Clear PVC sight glass level indicator fixed with 2 bulkhead fittings.

– A ventless lid and a filter vent were both installed on the top of the tank.

– Made on a 500 US gallons vertical tank.

The customer wanted to fit a larger tank to maximize the urea storage. He was using a 1000-liter IBC Tote, but that was not enough anymore. With a drawing of what he wanted, we did a piping-mounting on a 500 US gallon tank to satisfy the customer’s storage needs. We installed a 2″ PVC outer pipe along the vertical wall to fill the tank at waist height. Another 2″ PVC inner pipe was installed at 1-1/2″ from the bottom to prevent splashing and foaming during filling. It could very well have been used to pump the liquid as well. A 1″clear PVC level indicator was fixed to the wall for a better reading of the liquid level. The standard cover was changed for a ventless model. On the top of the tank, a 2″ fitting was installed to hold the new filter vent. An additional drain and 3/4″ ball valve were also installed at the bottom of the tank for drainage purpose.

2″ Welded HDPE Half Coupling (Polyboss)

– 2″ polyethylene (HDPE) fittings, natural white.

– Machined with a female connection thread (FNPT).

– Welded on a 35 gallon horizontal tank.

The customer wanted to put a tank in a specific place in his van to have enough room for the rest of his equipment. So he absolutely needed a 2” fitting, located at the very end, on top of the tank. Even though the available space was very limited, thanks to the plastic welding, it was possible to install a 2″ FNPT connection at the desired location. Indeed, no other type of connection would have allowed this type of assembly. The welded couplings take much less room to install than all other types of fittings, so they have a more flexible location options.

Cut and Welded HDPE Mounting Brackets

– For hanging a pump of 15 lb.

– Brackets are made of natural white polyethylene.

– Welded on a 3000 US gallon vertical tank.

To save space and simplify the connection of his pump, the customer wanted to hang his pump directly on the tank wall. With the pump in hand, we took all the required dimensions to be able to design the appropriate type of brackets to safely support the pump in place, but allowing it to be removable if necessary. We have therefore cut and welded to the tank, some natural white polyethylene (HDPE) brackets, which are perfectly adapted to the shape and weight of the pump.

Not sure if we can make it? Ask us!

Vertical Closed Top Storage Tanks

Vertical Closed Top Storage Tanks

Free Standing Horizontal Tanks

Free Standing Horizontal Tanks

Rectangular Utility Tanks

Rectangular Utility Tanks

1000 Litre IBC Tanks (Cage Tote)

1000 Litre IBC Tanks (Cage Tote)

Pick up Tanks

Pick up Tanks

Double Wall Tanks

Double Wall Tanks

Vertical Open Top Storage Tanks

Vertical Open Top Storage Tanks

Plastic Water Stock Tank

Plastic Water Stock Tank

Cone Bottom Tanks - Closed Top Plastic Tanks

Cone Bottom Tanks - Closed Top Plastic Tanks

Cone Bottom Tanks - Open Top Plastic Tanks

Cone Bottom Tanks - Open Top Plastic Tanks

Secondary containment basins

Secondary containment basins

Cage Tank Parts (IBC Tote)

Cage Tank Parts (IBC Tote)

Polypropylene and PVC Ball Valves

Polypropylene and PVC Ball Valves

Polypropylene and PVC Tank Fittings

Polypropylene and PVC Tank Fittings

Camlock Fittings

Camlock Fittings

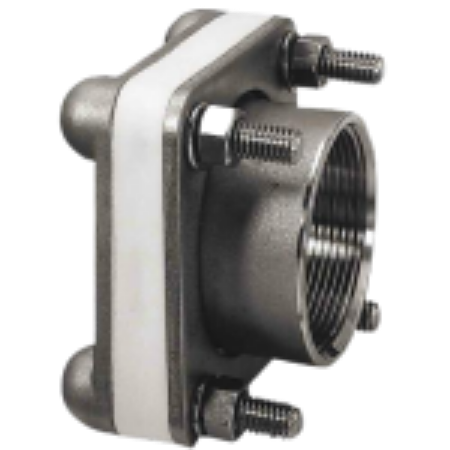

Stainless Steel Bolted Fitting

Stainless Steel Bolted Fitting

Polypropylene Threaded Reducer Nipples

Polypropylene Threaded Reducer Nipples

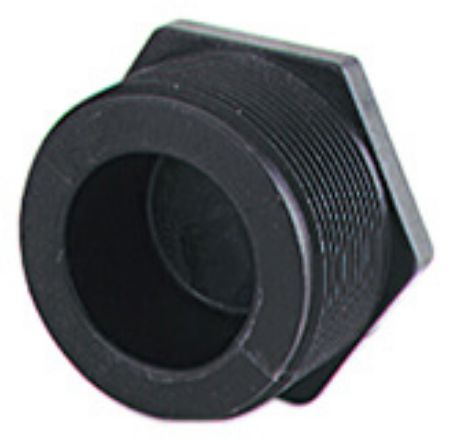

Polypropylene Threaded Reducer Bushings

Polypropylene Threaded Reducer Bushings

Hose Barb Fitting Adapter

Hose Barb Fitting Adapter

Vent Caps

Vent Caps

Filter Strainer Baskets

Filter Strainer Baskets

Threaded Pipe Nipples

Threaded Pipe Nipples

Polypropylene Tee Fitting, NPT Female Thread

Polypropylene Tee Fitting, NPT Female Thread

Polypropylene Cross Fitting, NPT Female Thread

Polypropylene Cross Fitting, NPT Female Thread

Drain Plugs

Drain Plugs

Elbow fittings

Elbow fittings

PVC Adapter, NPT Male Thread to Socket End

PVC Adapter, NPT Male Thread to Socket End

Polypropylene Threaded Pipe Couplings

Polypropylene Threaded Pipe Couplings

Closed Top Tank Lids

Closed Top Tank Lids

Fire Hydrant Adapters for Quebec

Fire Hydrant Adapters for Quebec

Replacement Gasket for Bulkhead Fitting

Replacement Gasket for Bulkhead Fitting

Level Indicator

Level Indicator

Miscellaneous accessories

Miscellaneous accessories

Potable Water Hoses

Potable Water Hoses

Liquid Suction and Discharge Hoses

Liquid Suction and Discharge Hoses

Liquid Discharge Hoses

Liquid Discharge Hoses

Assembled Liquid Discharge Hoses

Assembled Liquid Discharge Hoses

Hose Clamps

Hose Clamps

Fire Hose

Fire Hose

Food Grade Containers, Solid Walls and Bottom

Food Grade Containers, Solid Walls and Bottom

Food Grade Containers, Vented Walls and Bottom

Food Grade Containers, Vented Walls and Bottom

Attached Lids Plastic Containers

Attached Lids Plastic Containers

Industrial Plastic Containers, Solid Walls and Botton

Industrial Plastic Containers, Solid Walls and Botton

Sand and Salt Plastic Storage Bins

Sand and Salt Plastic Storage Bins

Containers - Lids and Covers

Containers - Lids and Covers

Containers - ID and Hot Stamp

Containers - ID and Hot Stamp

Containers - Dollies

Containers - Dollies

FDA Food Grade Plastic Pallets

FDA Food Grade Plastic Pallets

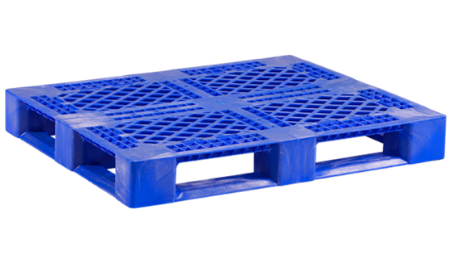

Industrial Plastic Pallets for Warehouse and Racking

Industrial Plastic Pallets for Warehouse and Racking

Export Plastic Pallet

Export Plastic Pallet

Display Plastic Pallets

Display Plastic Pallets

Drum Plastic Pallets

Drum Plastic Pallets

Plastic Pallet Boxes, Solid walls and Bottom

Plastic Pallet Boxes, Solid walls and Bottom

Plastic Pallet Boxes, Vented walls and Bottom

Plastic Pallet Boxes, Vented walls and Bottom

Insulated Plastic Pallet Boxes

Insulated Plastic Pallet Boxes

Tapered-wall Pallet Boxes

Tapered-wall Pallet Boxes

Removable walls Pallet Boxes

Removable walls Pallet Boxes

Pallet Boxes on Casters

Pallet Boxes on Casters

Lids - Pallet Boxes

Lids - Pallet Boxes

Pallet Box Bin Cart

Pallet Box Bin Cart

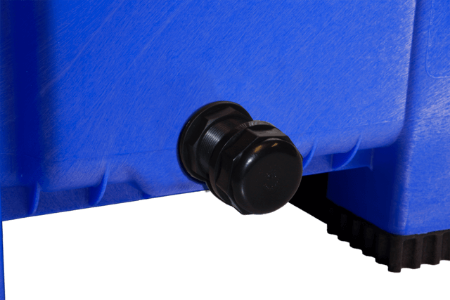

Drain Option for Pallet Boxes

Drain Option for Pallet Boxes

Custom Plastic Pallet Boxes

Custom Plastic Pallet Boxes

Food Grade Buggies / CFIA - FDA Carts

Food Grade Buggies / CFIA - FDA Carts

Industrial Poly-Box Trucks

Industrial Poly-Box Trucks

Carts Options and Accessories

Carts Options and Accessories