FAQ - Pallets

The static load is the maximum weight that a pallet can withstand when placed on the ground and the dynamic load is the weight that it can withstand when moved on the forks of a forklift.

Stackable pallets have bottom support so as to be able to be placed on top of another loaded pallet and provide stability during storage and transport.

Nestable pallets are also known as paddle pallets. Their surface includes holes to accommodate the legs of the top pallet. They can fit into each other to save space. These pallets maximize empty transport or warehouses.

A rackable pallet is engineered to be able to hold a specified amount of weight in an open span racking system. An open span rack has a front bar and a back bar and nothing in between. Rackable pallets may also be used in an edge rack where the pallet is supported by both side edges.

The solid pallet has a surface without drainage holes, but it can also have leg holes allowing the pallets to be nested to save space when empty (in warehouse or transport). The legs have a drainage hole to facilitate the evacuation of liquids. – Smooth: Full and smooth top, no corners difficult to wash thus preventing cross contamination. Molded in one piece. More slippery surface, therefore 7 mm retaining edge preventing items from slipping.

Any plastic pallet can be used as an export pallet, but most companies will choose the least costly pallet that will safely hold their shipment. When considering an export pallet, it is wise to consider the cost of product that is placed on the pallet. A $ 50,000 shipment sent on a $9.00 inadequate pallet is not best the way to save a few pennies.

A two way pallet is one that allows the forks of a forklift to enter on just two sides. This means they are raised by the deckboards and are better suited for lighter loads. However, there are plastic two way pallets available with a much higher weight capacity than wood. This allows your product to arrive in better shape and still be cost competitive.

A four way pallet is one that allows the forks of a forklift to enter on all four sides. In the case, pallets, this enables them to be raised by the stringers and so are best suited for heavier loads. Even so, plastic four way pallets offer far superior performance and ROI than wood pallets. They are more durable, have a higher weight capacity and should be considered in the context of your operation.

A food-grade plastic pallet complies with CFIA and FDA standards for use in the food industry. This compliance is essential when the pallet must have direct contact with the products. They can therefore be used directly in the transformation section.

You can, if you work with packaged products or in storage. This is the packaging, in this case, which must comply with the regulations of the industry.

It is true that most of the plastic pallets used on the market are black. This is because they are made from recycled plastics which is an excellent value for money. They come from plastic products of different colors considered as waste, which have been washed, fragmented and transformed into a new material that will be used to make new pallets. As a result, the mixture obtained gives a dark and unattractive color, which is corrected during production with the addition of black dyes which makes the whole thing uniform. In the end, nice black pallets are produced and in their turn, can be recycled at the end of their useful life cycle.

Call an expert

Did not find the information you were looking for?

Ask us your question directly!

Need assistance? Contact us at 450 471-2772

Vertical Closed Top Storage Tanks

Vertical Closed Top Storage Tanks  Free Standing Horizontal Tanks

Free Standing Horizontal Tanks  Rectangular Utility Tanks

Rectangular Utility Tanks  1000 Litre IBC Tanks (Cage Tote)

1000 Litre IBC Tanks (Cage Tote)  Pick up Tanks

Pick up Tanks  Double Wall Tanks

Double Wall Tanks  Vertical Open Top Storage Tanks

Vertical Open Top Storage Tanks  Plastic Water Stock Tank

Plastic Water Stock Tank  Cone Bottom Tanks - Closed Top Plastic Tanks

Cone Bottom Tanks - Closed Top Plastic Tanks  Cone Bottom Tanks - Open Top Plastic Tanks

Cone Bottom Tanks - Open Top Plastic Tanks  Secondary containment basins

Secondary containment basins  Cage Tank Parts (IBC Tote)

Cage Tank Parts (IBC Tote)  Polypropylene and PVC Ball Valves

Polypropylene and PVC Ball Valves  Polypropylene and PVC Tank Fittings

Polypropylene and PVC Tank Fittings  Camlock Fittings

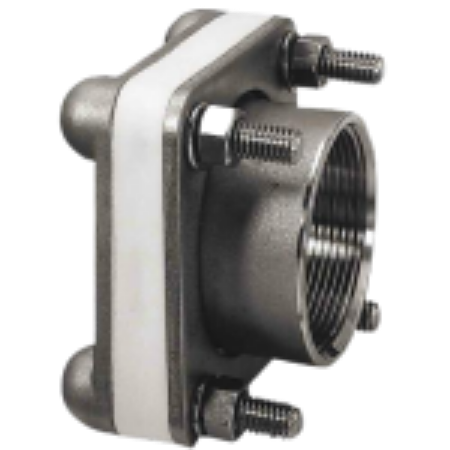

Camlock Fittings  Stainless Steel Bolted Fitting

Stainless Steel Bolted Fitting  Polypropylene Threaded Reducer Nipples

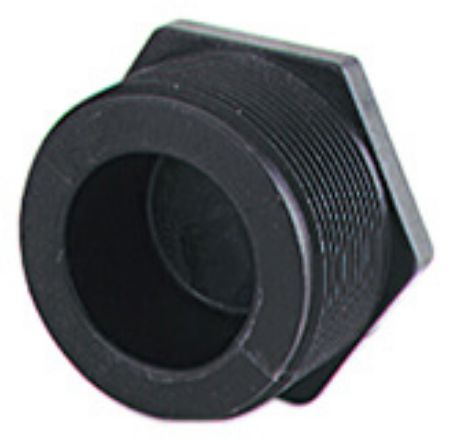

Polypropylene Threaded Reducer Nipples  Polypropylene Threaded Reducer Bushings

Polypropylene Threaded Reducer Bushings  Hose Barb Fitting Adapter

Hose Barb Fitting Adapter  Vent Caps

Vent Caps  Filter Strainer Baskets

Filter Strainer Baskets  Threaded Pipe Nipples

Threaded Pipe Nipples  Polypropylene Tee Fitting, NPT Female Thread

Polypropylene Tee Fitting, NPT Female Thread  Polypropylene Cross Fitting, NPT Female Thread

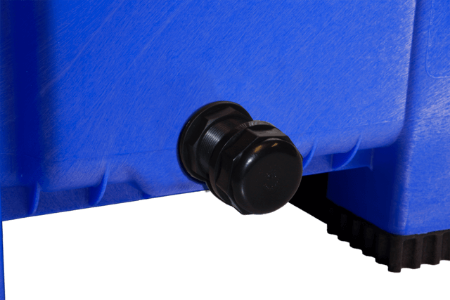

Polypropylene Cross Fitting, NPT Female Thread  Drain Plugs

Drain Plugs  Elbow fittings

Elbow fittings  PVC Adapter, NPT Male Thread to Socket End

PVC Adapter, NPT Male Thread to Socket End  Polypropylene Threaded Pipe Couplings

Polypropylene Threaded Pipe Couplings  Closed Top Tank Lids

Closed Top Tank Lids  Fire Hydrant Adapters for Quebec

Fire Hydrant Adapters for Quebec  Replacement Gasket for Bulkhead Fitting

Replacement Gasket for Bulkhead Fitting  Level Indicator

Level Indicator  Miscellaneous accessories

Miscellaneous accessories  Potable Water Hoses

Potable Water Hoses  Liquid Suction and Discharge Hoses

Liquid Suction and Discharge Hoses  Liquid Discharge Hoses

Liquid Discharge Hoses  Assembled Liquid Discharge Hoses

Assembled Liquid Discharge Hoses  Hose Clamps

Hose Clamps  Fire Hose

Fire Hose  Food Grade Containers, Solid Walls and Bottom

Food Grade Containers, Solid Walls and Bottom  Food Grade Containers, Vented Walls and Bottom

Food Grade Containers, Vented Walls and Bottom  Attached Lids Plastic Containers

Attached Lids Plastic Containers  Industrial Plastic Containers, Solid Walls and Botton

Industrial Plastic Containers, Solid Walls and Botton  Sand and Salt Plastic Storage Bins

Sand and Salt Plastic Storage Bins  Containers - Lids and Covers

Containers - Lids and Covers  Containers - ID and Hot Stamp

Containers - ID and Hot Stamp  Containers - Dollies

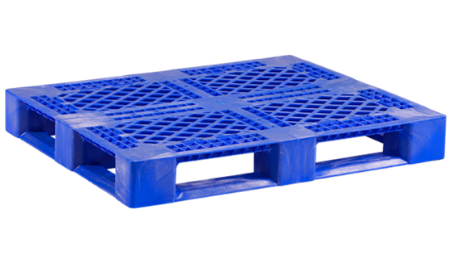

Containers - Dollies  FDA Food Grade Plastic Pallets

FDA Food Grade Plastic Pallets  Industrial Plastic Pallets for Warehouse and Racking

Industrial Plastic Pallets for Warehouse and Racking  Export Plastic Pallet

Export Plastic Pallet  Display Plastic Pallets

Display Plastic Pallets  Drum Plastic Pallets

Drum Plastic Pallets  Plastic Pallet Boxes, Solid walls and Bottom

Plastic Pallet Boxes, Solid walls and Bottom  Plastic Pallet Boxes, Vented walls and Bottom

Plastic Pallet Boxes, Vented walls and Bottom  Insulated Plastic Pallet Boxes

Insulated Plastic Pallet Boxes  Tapered-wall Pallet Boxes

Tapered-wall Pallet Boxes  Removable walls Pallet Boxes

Removable walls Pallet Boxes  Pallet Boxes on Casters

Pallet Boxes on Casters  Lids - Pallet Boxes

Lids - Pallet Boxes  Pallet Box Bin Cart

Pallet Box Bin Cart  Drain Option for Pallet Boxes

Drain Option for Pallet Boxes  Custom Plastic Pallet Boxes

Custom Plastic Pallet Boxes  Food Grade Buggies / CFIA - FDA Carts

Food Grade Buggies / CFIA - FDA Carts  Industrial Poly-Box Trucks

Industrial Poly-Box Trucks  Carts Options and Accessories

Carts Options and Accessories