FAQ - Tanks

The plastic tanks carry aone year warranty from date of purchase Should a defect appear within the warranty period, Agrico Plastics will supply a new, equivalent tank in replacement thereof. Agrico Plastics liability is limited to the value of the tank itself and specifically excludes the cost of installation and/or removal or consequential damages.

All tanks are embossed with a serial number that is 1/2″ in height. You will usually find the serial number by the fill-opening of the tank with the exception of large vertical tanks. Vertical tanks 5000 gallons and larger have the serial number embossed 48″-52″ up from the bottom of the tank on the sidewall in line with the gallonage markers.

Tans are manufactured from a linear, high-density polyethylene resin that provides outstanding environmental stress crack resistance. The resin is UV stabilized but by keeping the tank sheltered or indoors you will prolong the life of your tank.

Yes, it is safe to store water in the above ground tanks and below ground cistern tanks shown on our website. The resin used to manufacture these tanks meets FDA specifications for safe storage of potable water.

We have two grades of polyethylene tanks – premium and heavy duty. The premium tank is designed and manufactured to hold a product with a specific gravity up to 1.5, (12.5 pounds per gallon) at 21 degrees C. The heavy-duty tank is designed and manufactured to hold a product with a specific gravity up to 1.9, (15.8 pounds per gallon) at 21 degrees C.

We refer you to the paragraph above that relates to specific gravity/pounds per gallon. Because the wall thickness varies from top to bottom on a tank, it is not the best gauge for determining the quality of a tank. The very bottom of the tank is the thinnest part of the tank and is made that way to flex when the tank is empty or full. Generally the wall becomes thicker as you go from the top to the bottom of a vertical tank. This is done to increase resistance to head pressure created by the height of the liquid in the tank. The radius of the tank is thicker to increase strength where it is most critical. The actual weight of the tank is also not a good comparison when shopping for tanks. Just because a competitor may use more material in the tank does not make it a better tank. That is determined by the resin, mold design and the steps taken during the rotomolding process.

Polyethylene storage tanks have a maximum storage temperature of 49 degrees C. Contents with a temperature in excess of 49°C even for a short period of time-can weaken the tank’s structural integrity and make it susceptible to deformation and failure.

The tank itself does not have a minimum temperature rating. If you plan to keep the liquid in the tank and you know that it will freeze, make sure that you leave room for expansion. The most likely part to crack on the tank is the bulkhead fitting which can be easily replaced.

Several fertilizers and chemicals can be stored in Norwesco above ground tanks. We strongly recommend that you contact the chemical manufacturer to see if their product is compatible with high density, linear polyethylene. If they cannot answer your question, call our Customer Service department and they will be happy to research it for you. Try to have as much information available as possible such as the temperature of the product, the percentage of product (Ex: Hydrochloric Acid, 50%) etc.

No. We recommend that you do not store petroleum products in our tanks because they will soften the tank walls.

There is no good way to determine the life span of a polyethylene tank. Many variables can have an effect on the tank – what type of material is being stored in the tank? Is the tank used indoors or outdoors? If the tank is outdoors, what part of the country are you located in? Is the tank being used strictly for stationary storage or for transport? Each of these factors will have an effect on a polyethylene tank. Quelle est la durée de vie d’un réservoir?

If a tank is beginning to show its age, you will be able to see fine fissures or hairline cracks referred to as crazing. Look for crazing on the dome of a vertical tank in the area where sunlight is most intense. The top of a transport tank, which has been allowed to set outside all year, is a good place to look as well. These fine cracks will become more intense and visible as time goes on and will become stress cracks. Giving the tank a good hit with a baseball bat is as good a test as any. The resilience of a good tank will be obvious. A tank beyond its life expectancy will sound dull when struck and could crack as a result. It is better to check early and be safe versus losing valuable chemicals and incurring cleanup expense. When a tank is determined to be unsafe or you know it is getting old, it is best to make it a non-drinking water only tank.

Rigid piping must not be connected directly to a tank. Flexible connections are required between the tank fitting and the pump to allow for expansion and contraction of the tank as it is filled and as liquid is withdrawn. A good quality flexible hose is best. We also recommend proper support under heavy valves and fittings that may be attached to the tank fitting. These plumbing recommendations will also extend the life of the tank by reducing stress on the tank.

When bulkhead fittings are installed at the factory, a torque wrench with a special adapter is used to tighten them. Sometimes the fittings loosen and it may be necessary to tighten them. Without a torque wrench, our recommendation is to hand tighten the nut and then give it another 1/4 turn. Do not over tighten as this may pinch the gasket and cause the fitting to leak.

No, our tanks cannot be pressurized.

Tanks specifically designed for above ground use cannot be put underground. If it is put below ground, the weight of the earth around the tank will cause the walls to collapse. We offer tanks that are designed to be buried. See “Underground Tanks” section.

Proper installation requires a flat and smooth surface to provide adequate support. The bottom of the tank must be fully supported. A properly constructed concrete pad that is capable of supporting the contents of the tank is the best support and is recommended above 2,000 gallons. Other materials such as very flat blacktop, or contained, packed sand or pea gravel have been used successfully. All surfaces must maintain uniform support through freeze/thaw, erosion and other disturbances.

If you are planning on using your tank for potable water storage, you may want to rinse it with a very mild bleach solution to sanitize the tank and then rinse it again with clean water following the bleach solution rinse.

Over time, exposure to sunlight causes the plastic to stiffen which makes it more prone to cracking if the tank is put under large amounts of stress. All Plastic tanks are infused with an ultraviolet inhibitor that slows this hardening effect.

Call an expert

Did not find the information you were looking for?

Ask us your question directly!

Need assistance? Contact us at 450 471-2772

Vertical Closed Top Storage Tanks

Vertical Closed Top Storage Tanks  Free Standing Horizontal Tanks

Free Standing Horizontal Tanks  Rectangular Utility Tanks

Rectangular Utility Tanks  1000 Litre IBC Tanks (Cage Tote)

1000 Litre IBC Tanks (Cage Tote)  Pick up Tanks

Pick up Tanks  Double Wall Tanks

Double Wall Tanks  Vertical Open Top Storage Tanks

Vertical Open Top Storage Tanks  Plastic Water Stock Tank

Plastic Water Stock Tank  Cone Bottom Tanks - Closed Top Plastic Tanks

Cone Bottom Tanks - Closed Top Plastic Tanks  Cone Bottom Tanks - Open Top Plastic Tanks

Cone Bottom Tanks - Open Top Plastic Tanks  Secondary containment basins

Secondary containment basins  Cage Tank Parts (IBC Tote)

Cage Tank Parts (IBC Tote)  Polypropylene and PVC Ball Valves

Polypropylene and PVC Ball Valves  Polypropylene and PVC Tank Fittings

Polypropylene and PVC Tank Fittings  Camlock Fittings

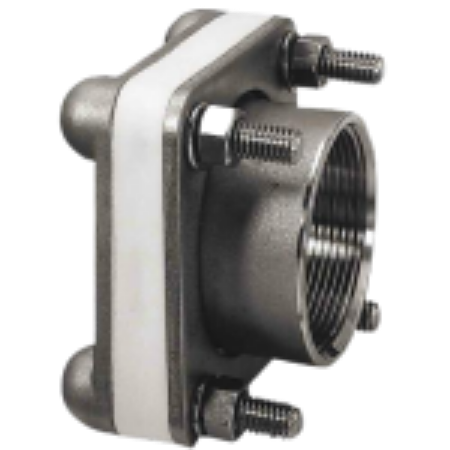

Camlock Fittings  Stainless Steel Bolted Fitting

Stainless Steel Bolted Fitting  Polypropylene Threaded Reducer Nipples

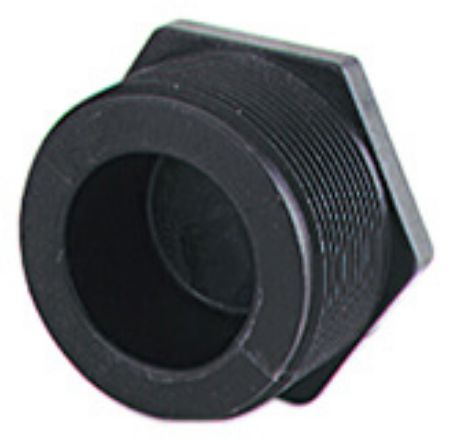

Polypropylene Threaded Reducer Nipples  Polypropylene Threaded Reducer Bushings

Polypropylene Threaded Reducer Bushings  Hose Barb Fitting Adapter

Hose Barb Fitting Adapter  Vent Caps

Vent Caps  Filter Strainer Baskets

Filter Strainer Baskets  Threaded Pipe Nipples

Threaded Pipe Nipples  Polypropylene Tee Fitting, NPT Female Thread

Polypropylene Tee Fitting, NPT Female Thread  Polypropylene Cross Fitting, NPT Female Thread

Polypropylene Cross Fitting, NPT Female Thread  Drain Plugs

Drain Plugs  Elbow fittings

Elbow fittings  PVC Adapter, NPT Male Thread to Socket End

PVC Adapter, NPT Male Thread to Socket End  Polypropylene Threaded Pipe Couplings

Polypropylene Threaded Pipe Couplings  Closed Top Tank Lids

Closed Top Tank Lids  Fire Hydrant Adapters for Quebec

Fire Hydrant Adapters for Quebec  Replacement Gasket for Bulkhead Fitting

Replacement Gasket for Bulkhead Fitting  Level Indicator

Level Indicator  Miscellaneous accessories

Miscellaneous accessories  Potable Water Hoses

Potable Water Hoses  Liquid Suction and Discharge Hoses

Liquid Suction and Discharge Hoses  Liquid Discharge Hoses

Liquid Discharge Hoses  Assembled Liquid Discharge Hoses

Assembled Liquid Discharge Hoses  Hose Clamps

Hose Clamps  Fire Hose

Fire Hose  Food Grade Containers, Solid Walls and Bottom

Food Grade Containers, Solid Walls and Bottom  Food Grade Containers, Vented Walls and Bottom

Food Grade Containers, Vented Walls and Bottom  Attached Lids Plastic Containers

Attached Lids Plastic Containers  Industrial Plastic Containers, Solid Walls and Botton

Industrial Plastic Containers, Solid Walls and Botton  Sand and Salt Plastic Storage Bins

Sand and Salt Plastic Storage Bins  Containers - Lids and Covers

Containers - Lids and Covers  Containers - ID and Hot Stamp

Containers - ID and Hot Stamp  Containers - Dollies

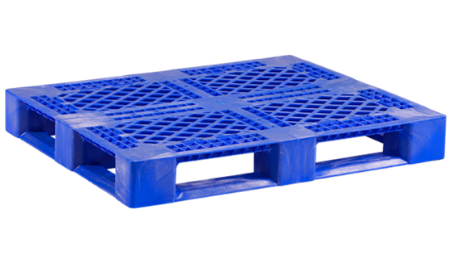

Containers - Dollies  FDA Food Grade Plastic Pallets

FDA Food Grade Plastic Pallets  Industrial Plastic Pallets for Warehouse and Racking

Industrial Plastic Pallets for Warehouse and Racking  Export Plastic Pallet

Export Plastic Pallet  Display Plastic Pallets

Display Plastic Pallets  Drum Plastic Pallets

Drum Plastic Pallets  Plastic Pallet Boxes, Solid walls and Bottom

Plastic Pallet Boxes, Solid walls and Bottom  Plastic Pallet Boxes, Vented walls and Bottom

Plastic Pallet Boxes, Vented walls and Bottom  Insulated Plastic Pallet Boxes

Insulated Plastic Pallet Boxes  Tapered-wall Pallet Boxes

Tapered-wall Pallet Boxes  Removable walls Pallet Boxes

Removable walls Pallet Boxes  Pallet Boxes on Casters

Pallet Boxes on Casters  Lids - Pallet Boxes

Lids - Pallet Boxes  Pallet Box Bin Cart

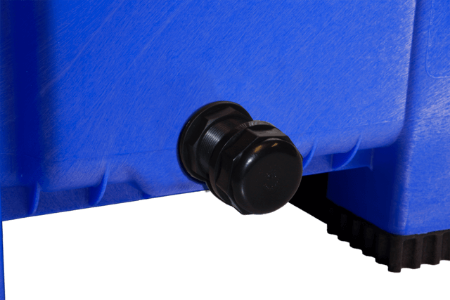

Pallet Box Bin Cart  Drain Option for Pallet Boxes

Drain Option for Pallet Boxes  Custom Plastic Pallet Boxes

Custom Plastic Pallet Boxes  Food Grade Buggies / CFIA - FDA Carts

Food Grade Buggies / CFIA - FDA Carts  Industrial Poly-Box Trucks

Industrial Poly-Box Trucks  Carts Options and Accessories

Carts Options and Accessories