HERE'S ONE OF THE HIDDEN PROBLEMS OF A POORLY CHOSEN BULK CONTAINER IN FOOD PLANTS…

Strangely, everyone finds it normal to have to scrub so much. "It happens often," they say. It's almost become a habit.

And that's where the real problem begins. Because the moment an irritant becomes routine, it's no longer questioned. It's just endured.

Teams compensate, extend the wash cycle, take more time… without ever questioning the tool itself.

Seriously, who decided this was normal?

- No. It's not normal at all.

A poorly chosen bulk container can turn what should have been a smooth day into a real headache: wasted cleaning hours, heavier HACCP audits, friction between production and quality. And yet, on paper, everything seemed fine.

A bulk container should never be a problem to manage. It's a tool that's supposed to help.

When it's well chosen, it disappears from daily operations.

When it's poorly adapted, it becomes a silent irritant that keeps coming back, day after day.

TABLE OF CONTENTS

In this article, we review the real on-the-ground issues related to bulk containers, from the initial problem to concrete solutions that change daily life in the plant.

Click on a section to go directly to the topic.

- What is a plastic bulk container and what is it used for?

- Real life on the floor: why irritants fly under the radar?

- The hidden costs of poorly adapted bulk containers

- Why so many plants make the wrong choice?

- The 3 questions to ask before buying an industrial bulk container

- Real case: what a well-chosen bulk container concretely changes?

- The 6 essential criteria for choosing the right bulk container (and pitfalls to avoid)

- Hygiene and HACCP compliance: a real issue

- The most frequent objections and how to overcome them

- Why trust Agrico Plastiques for choosing your bulk containers?

- Bonus: Quick checklist – to review before any purchase

WHAT IS A PLASTIC BULK CONTAINER?

AND WHAT IS IT USED FOR?

A plastic bulk container isn't just a "big bin." On the production line, it's the container that carries the flow.

It's a large, robust industrial bin made of high-density polyethylene (HDPE), consisting of a base that's like a pallet surrounded by four walls.

- The most common base formats are 40" x 48" and 48" x 48".

- Heights generally vary from 25" to 52".

The bulk container is designed to handle, transport, and store bulk products in a single movement, with a forklift or pallet jack.

There are versions with solid or perforated walls.

Concretely, it allows you to:

- Move large volumes without multiplying handling operations

- Group production in a stable and safe container

- Drain, cool, or freeze products in bulk

- Standardize internal and external transportation

- Contain products that are difficult to palletize

- Reduce disposable or single-use packaging

In food processing (meats, poultry, fruits, vegetables, seafood, fish), the bulk container quickly becomes a central tool: it moves from production to washing, from the cooler to the freezer, from the dock to the truck, then to the customer.

In agriculture, it spends entire days in the fields for harvesting.

In industry, waste management, or logistics, it replaces dozens of small containers that are difficult to manage and stabilize.

When it's well chosen, the bulk container simplifies work.

When it's poorly adapted… it complicates everything, without always knowing why.

REAL LIFE ON THE FLOOR:

WHY IRRITANTS FLY UNDER THE RADAR?

On the floor, a bulk container is never static.

It's the container that follows the product everywhere: production, storage, transport, freezing, washing, delivery.

Depending on the sector, it must withstand humidity, impacts, stacking, washing, and sometimes more intense handling such as dumping with rotary forks. Operators load it with forklifts, move it with pallet jacks, stack it on racks, place it on conveyors. It circulates non-stop.

And for some, the circuit doesn't stop there. They leave the plant to be shipped to the customer. Once there, they still need to be efficient, stable, and optimize space at the customer's location, often under conditions you don't directly control.

But when something gets stuck; endless cleaning, trapped condensation, container difficult to move, costly empty returns, teams often adapt. They work around the problem, improvise, slow down a bit… then continue.

Nothing completely stops. It just slows down enough to fly under the radar.

So, nobody officially records it, but everyone feels it. And over a day, then a week, then a year, it's these small workarounds that eat away at time, energy, and performance.

THE HIDDEN COSTS OF POORLY

ADAPTED BULK CONTAINERS

Every poorly chosen purchase (because it doesn't meet the real need on the floor) hides impacts that cost the company dearly and exhaust teams, often without anyone even realizing it.

At the moment, nothing seems critical. Production is running. Washing gets done. The containers are there. But in the background, irritants accumulate. And it's always the same ones that come back.

Each friction adds up, day after day:

- Endless cleaning = 2 to 3 hours per day for a team of 4 people. Over a year, that's complete weeks of production that disappear.

- Condensation or drying out = degraded products, quality rejections, production rework, sometimes even unplanned line stoppages.

- Empty returns = paying a truck to transport air. Between 20 and 30% of transportation costs going to complete waste, with each return.

- Operational incompatibilities = blockages on conveyors, risky maneuvers, product breakage, equipment damage... and sometimes even operator injury.

- Poor design or specifications = unsuitable base, wrong dimensions, walls that bulge when filled, problematic color, unstable stacks, lower stacking than expected.

Individually, these problems seem minor.

- Together, they drive up costs insidiously.

This is exactly how recurring costs take hold.

- Not through one big mistake, but through an accumulation of small compromises that became "normal."

WHY SO MANY PLANTS MAKE

THE WRONG CHOICE?

This problem isn't one person's mistake.

It's not the production manager who had to launch a project quickly, nor the procurement manager, nor the finance person.

In reality, this wrong choice is almost always the direct result of daily pressure: cost pressure, lack of time to plan, urgent need that requires an immediate solution.

When there's urgency, it becomes impossible to wait for the right bulk container. You need one right away. In stock.

So you choose the one that seems "correct," or the one that's fastest to get, or the cheapest, because it looks like it will do the job. If there's no time to think, to ask the right questions, to do a trial run on the floor, and on top of that, there's no clear standardization plan, it becomes almost inevitable to end up with a multitude of different models.

The problem isn't having several models. The problem is that none of them is truly optimal.

In practice, we choose the cheapest bulk container, without mapping the complete flow: handling, washing, stacking, rack storage, freezer, transport, customer. We end up with bulk containers that, visually, seem to serve operations well, but that, in the background, constantly slow them down.

Result: bulk containers that looked good on paper, satisfactory for the wallet... but that get stuck somewhere in the operations chain from their first real complete cycle.

At that point, it's too late to think. You have to react.

And that's when it starts to hurt, to cost dearly.

THE 3 QUESTIONS TO ASK BEFORE

BUYING AN INDUSTRIAL BULK CONTAINER

1. What concrete problem needs to be solved on the floor?

Before even choosing a bulk container, you need to ask yourself what your irritants are, where employee complaints come from, what points audits bounce back on.

Very often, bulk containers are sought to solve this kind of problem:

- Too much handling of small bins to manipulate one by one

- Products difficult to palletize correctly

- Unstable pallets of bins, wrapped in plastic film that comes undone

- Constant transfers of containers between stages that waste time

- Teams working more, for lack of a suitable container

On the floor, this translates into repetitive gestures, unnecessary back-and-forth, time loss, and fatigue that sets in.

Before getting them, you need to know how to identify where things are really getting stuck in your flow:

- At washing, because too many small bins take time to clean

- In production, because handling is fragmented and not fluid

- In storage, because products store poorly or take up too much space

- In identifying a lot that is spread across too many separate bins

- In transport, because pallets are unstable or poorly optimized

- At the customer's, because the delivery method complicates recovery or pickup

As long as the real problem isn't clearly named, there's a high risk of buying bulk containers randomly, without knowing which characteristics to look for to really solve the problem. They risk compensating for or shifting the problem and acting, ultimately, as a temporary solution, when a well-chosen bulk container could really simplify the entire process.

2. What is the real objective or desired gain?

This question seems simple, but on the floor, it's rarely clarified. Often, people say they want to "improve operations," without specifying what or where. Result: you choose a bulk container that does a bit of everything, but excels nowhere.

On the ground, however, the objectives are very concrete:

- Reduce time spent washing

- Decrease manual handling and repetitive gestures

- Save space in the warehouse, cooler, or trucks

- Stabilize stacks to avoid breakage

- Simplify compliance and audits

- Secure movements and reduce risks for employees

When the objective isn't clear, teams compensate.

They work faster in some places, slower in others.

They accept compromises because "it works anyway."

A good choice always starts with a simple question: What do I want to concretely improve on the floor, starting tomorrow morning?

3. How will you measure the return on investment (ROI)?

The ROI of a bulk container is almost never seen on the purchase invoice. It's seen in daily operations, where no one really takes the time to measure.

On the floor, the return on investment manifests through:

- Less time spent washing

- Less breakage and containers set aside

- Less packaging and disassembly time

- Fewer quality complaints

- Successful audits

- Fewer unplanned stoppages

- Faster bulk handling

Without a clear method to measure real impact, a phenomenon sets in: we get used to the irritants. Teams compensate. Adjustments become reflexes. And when something becomes a reflex, we no longer question it; we just endure it.

It's precisely at that moment that "bad surprises" appear: not at purchase, but several months later, when you realize the bulk container never delivered the expected gains.

REAL CASE: WHAT A WELL-CHOSEN BULK CONTAINER CONCRETELY CHANGES?

+ 25% PRODUCTION, - 40% CLEANING

Before detailing how to properly choose your bulk container, let's look at a real case that Agrico Plastiques supported. With the right questions, the right understanding of the flow, and help from production, logistics, and quality teams, we succeeded in eliminating irritants related to poor equipment.

Before

A Quebec meat processing plant was using a mixed fleet of bulk containers purchased over the years — according to the specials of the moment. Result: three different models on the floor, different heights, all different bases, unknown load capacities, incompatibility with the main washer and meat dumper.

At the end of each shift, the washing team spent nearly two hours "catching up" on the most finicky containers: hard-to-clean corners, stagnant water that doesn't drain, endless drying. During production, the team transferred the less suitable bulk containers to another room and searched the floor for compatible models. Time loss and inefficiency. Internal and external audits often ended with remarks about hygiene and drainage.

After

By mapping the complete flow, from receiving, cutting, dumping, cooling, freezing, warehouse to shipping, we standardized their fleet with a single family of bulk containers with dimensions adapted to racks, smooth walls, with integrated drain, base compatible with pallet jacks and washer.

Results after three months:

- Washing time reduced by 40%

- Less time wasted on the floor

- Fewer quality rejections related to cross-contamination

- More stable stacks in coolers and freezers

- Production increased by 25% in 3 months

The production manager summarized it simply:

"Employees no longer talk about bulk containers on the floor. Everything runs smoothly, we're much more fluid, and production has increased by 25%. It completely changed our daily operations!"

THE 6 ESSENTIAL CRITERIA FOR CHOOSING THE RIGHT BULK CONTAINER (AND PITFALLS TO AVOID)

Choosing a food-grade or industrial bulk container is never a simple equipment purchase. It's a decision that directly influences operational fluidity, product safety, team workload, and real long-term costs.

A poorly adapted container doesn't always "appear" problematic at first. It works… until the day teams start adapting around it: repeated breakage, heavier handling, time lost washing, limited stacking, constant adjustments.

Before even comparing models or prices, it's essential to properly define the real application of the bulk container and the context in which it will operate, day after day.

1. Analyze the product and its environment

Everything starts with the product you put in the container… and with the environment in which it will operate. The plastic must be compatible with your application: food certification (if necessary), resistance to cleaning products, disinfectants, solvents, and especially to real usage conditions.

It's essential to validate the temperatures to which the container will be exposed. A container can perform at room temperature, but behave differently in cold rooms, in freezing, or during hot water washing.

High-density polyethylene (HDPE), with its continuous use range from -28°C to 49°C, is particularly suited to these demanding environments as well as to rapid temperature changes.

- The costly trap

In a plant, it's very rare for a bulk container to remain in a single environment at all times: it goes from production to the cold room, from the dock to the truck, then returns to be washed with hot water and after several handlings, it can be stored in a freezer.

The frequent mistake is to choose a rigid plastic that performs well at room temperature, without considering what happens in the cold. Some materials, like polypropylene, can perform very well in dry, temperate environments, but become brittle when exposed to freezing or thermal shocks.

Result: cracks, ruptures, sudden breakage, often at the worst moment.

On the floor, the consequences are immediate:

- Product losses

- Contamination risks

- Employee safety

- Premature replacement of containers

- Impression that "it's normal" to have to buy them regularly

In the majority of food and industrial environments, high-density polyethylene (HDPE) remains the safest choice, as it maintains its mechanical strength even at low temperatures. However, in addition to the material, the manufacturing process plays an important role in impact resistance and equipment durability over the long term, depending on usage conditions.

2. The manufacturing process: what you don't see, but makes all the difference

The manufacturing process of a bulk container directly influences its impact resistance, its real load capacity, its behavior in cold conditions, its durability, and its repairability. Two bulk containers that look visually similar can react completely differently after a few weeks of use. On the floor, it's a container set aside "as a precaution," or unconsciously reserved for certain tasks.

Rotomolding: uniform robustness and tolerance to difficult environments

Rotomolding consists of rotating a heated mold on three axes to distribute the plastic uniformly. The molding process is long (10 to 15 containers per day) and the result is a bulk container without internal tension, which gives a more malleable, more flexible plastic.

On the ground, rotomolded containers stand out for:

- Excellent impact resistance, even at low temperature

- Good plastic flexibility, which absorbs impacts

- High durability in cold, humid, or outdoor environments

- Superior hygiene, ideal for food environments

In practice, rotomolding is highly valued in food environments, cold rooms, freezing, and applications where the container undergoes repeated impacts and where the need for very smooth walls is essential for exemplary sanitation.

Limitations to consider:

- Less structurally rigid for very high stacking or concentrated loads

- Not compatible with heavy racking or rotary forks

- Load capacity generally lower than structured foam injection

- Containers with solid walls and bottom only

Injection with structured foam: the reference for intensive industrial use

Injection with structured foam is an evolution of traditional injection. A gas is injected during molding, creating micro air pockets inside the wall. The result gives a very rigid internal structure and much lighter than traditional injection. It's the most used process for industrial bulk containers intended for intensive handling.

On the ground, this process offers:

- Excellent impact resistance

- High load capacity, even when stacked

- Significant weight reduction

- Increased stability on forks

- Compatibility with racking and rotary forks

- Possibility of containers with perforated walls and bottom

In practice: it's the safest choice for industrial environments, heavy loads, high stacking, and operations where the container constantly circulates by forklift.

- The costly trap

Two bulk containers can seem identical on a technical sheet, but behave completely differently on the floor. The reason is simple: the manufacturing process directly influences the internal structure, real load capacity, impact resistance, and overall durability.

A common mistake is to rely solely on nominal data without understanding how the container is manufactured. Some bulk containers, very rigid at first glance, can actually be fragile, because they're poorly adapted to your internal handling.

In real conditions, this translates into cracks at lifting points, containers set aside by operators "because they're dangerous," or stacks that become unstable. In industrial settings, injection with structured foam is often preferred, as it offers an excellent compromise between strength, lightness, and impact resistance.

But, again, in some cases, bulk containers manufactured by the rotomolding process may be preferred in contexts where sanitation, cold, and impact tolerance take priority over high stacking.

3. Consider longevity, impacts, and repairability: single, double, or triple wall

Then comes the choice of walls. This choice must be made in direct connection with your floor reality.

- Single wall: light, manageable, and economical. Works well for solid products. Limitations: repeated impacts, intensive freezing, liquids.

- Double wall: with polyurethane insulating foam injected between the two walls. It acts like a mini industrial cooler. Ideal for cold, frozen, or liquid products (fish, seafood). Caution: a perforation condemns the container, as water can infiltrate between the walls through the blown foam.

- Triple wall: for the most demanding environments. Withstands impacts, resists intensive washing, can be repaired by plastic welding in case of partial or complete perforation of a wall. Higher investment, but the return on investment is largely repaid by longevity and reduction of breakage.

- The costly trap

There are choices that sometimes seem secondary during purchase, but that have a direct impact on daily operations, such as solid or perforated walls, smooth or reinforced, single, double, or triple wall, with or without drain. It's often these details that extend washing time, complicate drying, or make audits more demanding.

The frequent mistake is to believe that solid walls automatically solve hygiene issues. In reality, when the bulk container hasn't been designed to drain or dry well, water remains trapped at the bottom or in certain angles and corners of the reinforcement grooves on the walls. On the floor, this translates into containers that look visually clean, but require re-washing or additional drying time.

A well-designed bulk container, with smooth walls, a drain, and characteristics adapted to real use, becomes almost invisible in daily operations. It washes quickly, dries well, and doesn't generate unnecessary discussions between teams.

4. Properly determine dimensions and load capacities

The dimensions of the bulk container aren't just a question of theoretical volume. They directly determine how the container will behave in your plant.

1- Start by calculating the real useful volume you need.

Make sure the interior dimensions of the bulk containers match well with the exterior dimensions of your goods.

The objective is clear: maximize bulk storage, contain a complete lot, or simply contain the maximum possible, avoiding unnecessarily wasted space, otherwise you lose inches, even square feet per container.

2- Then, look at the exterior dimensions with a critical eye.

The container must fit everywhere: doors, conveyors, racks, washers, freezers, trucks… and also at your customers'. A container that's too wide or too tall can become an invisible obstacle forcing detours, additional handling, reduced stacking, and more expensive transportation costs. This kind of constraint never officially blocks a line. It just forces one more trip, stacking less high, or accepting that "it fits… but just barely."

For optimal space optimization or for truly functional operations, if the standard bulk containers offered on the market don't correspond to your need, it's possible to manufacture them custom-made according to your specific need. They can be lower, higher, wider, or longer.

For more details on custom bulk containers, contact one of our advisors who will guide you

→ Fill out the form

→ Or chat with an advisor: 450-471-2772

3- Available height in each zone is often underestimated.

A simple stacking calculation allows you to know if you can stack two, five, or ten containers in the warehouse, or two to five in a truck, while respecting safety standards. This calculation directly determines your maximum operational flow and your real capacity to absorb production peaks.

It's equally crucial to respect the maximum loads specified for each bulk container. The bottom container of a stack must support the weight of all containers stacked above, plus its own weight and content. Exceeding this load limit exposes the container to the risk of deformation, cracks, or even catastrophic rupture.

These load limits exist to protect three elements simultaneously: the integrity of the contained material (which must not be damaged by an unstable stack), the durability of the bulk container itself, and especially the safety of employees who could be injured in case of collapse or spillage.

- The costly trap

The mistake is to validate the bulk container for a single application or a single workstation, then discover later that it doesn't work elsewhere. This leads to mixed fleets, impossible stacking, a loss of standardization that complicates the entire chain.

When the bulk container's typical day is well analyzed from the start – and all stakeholders from different departments are involved in the analysis, the choice becomes not only informed, but reassuring.

The bulk container stops being a compromise and becomes a durable ally for all operations.

5. Think about handling so it flows smoothly

On the floor, a bulk container must move without unnecessary effort. Its base is therefore a critical element. It must be compatible with all your equipment: pallet jacks, forklifts, rotary forks, dumpers, conveyors, and washers.

- A poorly chosen base forces operators to compensate : adjust the forks, slow down maneuvers, avoid certain areas. These repeated small adjustments end up slowing down the entire chain.

- Choosing a well-designed leg or runner base allows stability on the forks and smooth compatibility with your equipment.

To secure this choice, it's essential to require complete specifications for static and dynamic loads, as well as real stacking capacity. This data makes the difference between a container that "does the job" and a container that becomes an obstacle. By compensating, these adjustments become reflexes. And when something becomes a reflex, we no longer question it: we just endure it.

- The costly trap

The base of the bulk container is often the least discussed element during purchase, even though it's in direct contact with all your handling equipment. Forklift, pallet jack, rotary forks, dumpers, conveyor, truck: everything goes through the base.

The classic mistake is not testing the container with all equipment, or forgetting the reality at the customer's location. A poorly adapted base leads to constant adjustments, conveyor blockages, time losses, and accident risks. Conversely, a well-chosen base allows effective standardization: no fork modifications, no special adaptation in the workflow, no time loss. Employees operate better, faster, and with less stress.

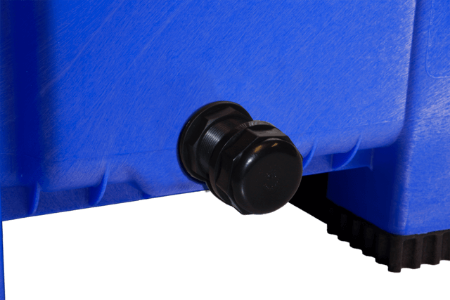

6. Integrate accessories and options that matter: think HACCP

Certain accessories and options, often added after the fact, can really transform daily efficiency:

- A cart or casters to facilitate mobility in restricted spaces

- A lid to protect the contents

- A drain to improve emptying and drying (crucial for HACCP)

- Color codes to simplify traceability (allergens, raw/cooked)

- Custom dimensions to maximize space

- Identification by hot stamping to secure and facilitate locating your bulk containers in your plan or that leave your plant

Taken individually, these elements may seem secondary. Together, they often make the difference between a tolerated bulk container and a bulk container truly adapted to daily operations. Teams work more easily, handling is smoother, production rhythm is more constant, and pressure drops on the floor.

But in terms of quality and compliance, their impacts go even further.

- The costly trap

The frequent mistake is seeing accessories as "options to add later" rather than as elements integrated into the initial choice. Result: a basic bulk container that works "well enough," but never really simplifies operations.

Waiting after purchase to add a drain, lid, or color codes means additional costs, field modifications, and a period where the container doesn't function at its full potential. Teams continue to compensate, slow down, look for workarounds. A well-chosen bulk container from the start, with appropriate accessories integrated, immediately becomes efficient. It helps. It no longer complicates.

HYGIENE AND HACCP COMPLIANCE:

A REAL ISSUE

In a HACCP plan, a bulk container is never neutral: it can either simplify an audit or become the black mark that comes back in every report. Your quality teams know this very well. A poorly chosen bulk container means impossible-to-wash corners, stagnant water difficult to drain, residue that sticks in grooves, and cross-contamination risks.

By choosing a bulk container adapted to your sector: food certification, smooth walls, effective drainage, compatibility with your cleaning products and water temperatures, you transform an irritant into an asset.

The MAPAQ inspector immediately sees clean surfaces, complete drainage, color codes by zone, and clear lot identification.

Result: shorter audits, fewer non-conformities, and especially a team that no longer spends its evenings "catching up" on washing.

Not sure if your bulk containers are compliant for your next audit?

Let's check it together.

→ Fill out the form

→ Or speak directly to an advisor: 450-471-2772

THE MOST FREQUENT OBJECTIONS

AND HOW TO OVERCOME THEM

1. "It's too expensive"

On the floor, the purchase price is what we see first. But the real cost of a bulk container is never calculated per unit. It's calculated per year, in real terms.

A more fragile container means:

- More unexpected breakage

- More emergency replacements

- More time lost washing

- More production stoppages or slowdowns

Very often, a "cheap" container means less material, therefore a lighter structure… and less durable. Each crack, each deformation becomes an irritant that accumulates.

Field example:

A quality bulk container may cost 30% more at purchase. But if it lasts 15 years instead of 8, washes faster, and reduces time spent in the washing area by 40%, the calculation is quickly done. The return on investment is no longer measured in years… but in months.

How to overcome this objection:

Test 2 or 3 units in real conditions for a few weeks.

Time:

- Washing time

- Stack stability

- Ease of handling

- Operator reactions

The floor always gives the real answer.

2. "I'm afraid of making a mistake"

This fear is legitimate. And honestly, it's healthy. Nobody wants to be the one who "chose the wrong container."

The problem isn't being afraid. The problem is choosing without really checking the entire work of the bulk container, without testing.

In a plant, a bulk container never experiences a single operation. It's filled, moved, emptied, washed, stacked, transported… then handled at the customer's. If a single step hasn't been validated, that's often where it breaks.

Field example:

A container works very well in production. But at washing, water stagnates. In the freezer, it becomes more rigid. In transport, stacking is limited. Result: each department compensates in its own way… Until the day a worried operator refuses to use it because it's become "dangerous."

How to overcome this objection:

Involve from the start:

- Operations

- Quality

- Logistics

- Purchasing

Validate a complete cycle of the bulk container at each stage of the process. When everyone has been consulted, the choice becomes reassuring… and assumed.

3. "We're used to our current containers"

This is probably the most frequent objection… and the most costly. Habit gives a false sense of control. We adapt. We work around. We slow down a bit. Then a bit more. And by compensating, irritants become reflexes.

Field example:

Operators already know which containers to avoid. They stack less high "to be sure." They take more time washing "as a precaution." They're careful in transport "because it moves." Everyone works harder… to get the same result.

How to overcome this objection:

A well-standardized and well-chosen container fleet:

- Simplifies handling

- Stabilizes stacking

- Speeds up movements

- Reduces unnecessary discussions

When equipment helps instead of slowing down, the difference is felt from the first week.

4. "It's too complex to change"

Changing always requires effort, that's true. But the real question is rarely asked: What is the cost of changing nothing? When:

- Performance stagnates

- Breakage repeats

- Washing takes too long

- Team morale drops

Inaction becomes a silent brake on profitability.

Field example:

We keep the same containers because "it's not the right time." But delays accumulate. Stacks are lower. Back-and-forth increases. Employees compensate… until exhaustion.

How to overcome this objection:

Nobody asks you to replace everything at once. Start small:

- One line

- One zone

- One product type

Test, measure, adjust. Very often, a single well-targeted improvement creates enough gains to finance the rest.

WHY TRUST AGRICO PLASTIQUES

FOR YOUR BULK CONTAINERS?

We hear these objections every day. And we understand them. That's why we exist. At Agrico Plastiques, we don't just sell you a bulk container and wish you good luck. For decades, our team has been on the ground with you: meat plants, poultry, fish, fruits and vegetables, confectioneries, industrial bakeries, distribution centers, recycling and waste management.

We see the same irritants come back: endless washing, containers that crack in the cold, incompatibilities with washers or conveyors, handling problems, HACCP audits that drag on, space losses, time losses, and production lines that get stuck.

Our role at Agrico Plastiques

Our role is to translate these irritants into concrete solutions. We know each sector of activity very well and the equipment that works well in each of them.

However, each plant is unique, has its share of challenges and constraints. That's why you explain your reality to us: pace, operating temperature, product type, space constraints, washing, transport, etc.

We want to know where things are getting stuck at your location, what bothers you, and what your specific objective is — and we'll propose a solution based on a model of bulk containers tested in environments similar to yours.

We don't push "the special of the month"

We work with what will really hold up in your plant and protect your productivity for several years. Our greatest reward is when our customers tell us that our advice and products have made a big difference in their plant. Our ultimate goal is for you to be satisfied with your purchase, because it really works.

You have a project and don't want to make a mistake?

Let's evaluate it together.

You'll get a free analysis of your project.

→ Fill out the form

→ Prefer to speak to someone? Call us at 450-471-2772

BONUS: QUICK CHECKLIST –

TO REVIEW BEFORE ANY PURCHASE

To help you quickly validate your next purchase, here's a quick checklist to keep handy:

- Is the plastic food-grade, and compatible with all your products that will come into contact with the bulk container?

- Are the dimensions and interior volume optimal for your operations?

- Are the load capacities on the ground, on forks, and stacked suitable for your operations?

- Is the bulk container base compatible with your equipment and trucks?

- Is the model compatible with your cleaning method and your HACCP standards?

- Could accessories (casters, lid, drain, color codes) save you time?

- Have you tested the container in your complete flow: production, washing, storage, transport, customer?

- Have you validated stack stability in real conditions (cooler, freezer, truck)?

- Who at your location (production, quality, logistics, purchasing) has validated this choice?

- Can you concretely measure the ROI (washing time, breakage, handling, audits)?

- Does the supplier offer technical support and an honest warranty?

- Do you have a transition plan to standardize your fleet progressively?

READY TO OPTIMIZE YOUR OPERATIONS?

Here's your next step: print this guide, tour your plant with the checklist in hand, talk with your operators, your quality people, your washing and logistics supervisors.

Identify irritants together: washing time, drying, stack instability, lack of space, frequent breakage, unsuitable volume, incompatible base, team discomfort.

Contact us for a free evaluation of your bulk container fleet

We'll analyze your real flow and propose standardization or progressive improvement of your fleet.

→ Fill out the form

→ Or Contact us: 450-471-2772

And if your bulk containers were stealing up to 30% of your efficiency, well chosen, they'll give it back to you, without expanding the plant, without hiring additional employees, and without turning everything upside down at once.

You already have the teams and the lines.

We'll help you give them the right tools.

Agrico Plastiques

Your trusted partner for food-grade and industrial plastic handling equipment.

Vertical Closed Top Storage Tanks

Vertical Closed Top Storage Tanks

Free Standing Horizontal Tanks

Free Standing Horizontal Tanks

Rectangular Utility Tanks

Rectangular Utility Tanks

1000 Litre IBC Tanks (Cage Tote)

1000 Litre IBC Tanks (Cage Tote)

Pick up Tanks

Pick up Tanks

Double Wall Tanks

Double Wall Tanks

Vertical Open Top Storage Tanks

Vertical Open Top Storage Tanks

Plastic Water Stock Tank

Plastic Water Stock Tank

Cone Bottom Tanks - Closed Top Plastic Tanks

Cone Bottom Tanks - Closed Top Plastic Tanks

Cone Bottom Tanks - Open Top Plastic Tanks

Cone Bottom Tanks - Open Top Plastic Tanks

Secondary containment basins

Secondary containment basins

Cage Tank Parts (IBC Tote)

Cage Tank Parts (IBC Tote)

Polypropylene and PVC Ball Valves

Polypropylene and PVC Ball Valves

Polypropylene and PVC Tank Fittings

Polypropylene and PVC Tank Fittings

Camlock Fittings

Camlock Fittings

Stainless Steel Bolted Fitting

Stainless Steel Bolted Fitting

Polypropylene Threaded Reducer Nipples

Polypropylene Threaded Reducer Nipples

Polypropylene Threaded Reducer Bushings

Polypropylene Threaded Reducer Bushings

Hose Barb Fitting Adapter

Hose Barb Fitting Adapter

Vent Caps

Vent Caps

Filter Strainer Baskets

Filter Strainer Baskets

Threaded Pipe Nipples

Threaded Pipe Nipples

Polypropylene Tee Fitting, NPT Female Thread

Polypropylene Tee Fitting, NPT Female Thread

Polypropylene Cross Fitting, NPT Female Thread

Polypropylene Cross Fitting, NPT Female Thread

Drain Plugs

Drain Plugs

Elbow fittings

Elbow fittings

PVC Adapter, NPT Male Thread to Socket End

PVC Adapter, NPT Male Thread to Socket End

Polypropylene Threaded Pipe Couplings

Polypropylene Threaded Pipe Couplings

Closed Top Tank Lids

Closed Top Tank Lids

Fire Hydrant Adapters for Quebec

Fire Hydrant Adapters for Quebec

Replacement Gasket for Bulkhead Fitting

Replacement Gasket for Bulkhead Fitting

Level Indicator

Level Indicator

Miscellaneous accessories

Miscellaneous accessories

Potable Water Hoses

Potable Water Hoses

Liquid Suction and Discharge Hoses

Liquid Suction and Discharge Hoses

Liquid Discharge Hoses

Liquid Discharge Hoses

Assembled Liquid Discharge Hoses

Assembled Liquid Discharge Hoses

Hose Clamps

Hose Clamps

Fire Hose

Fire Hose

Food Grade Containers, Solid Walls and Bottom

Food Grade Containers, Solid Walls and Bottom

Food Grade Containers, Vented Walls and Bottom

Food Grade Containers, Vented Walls and Bottom

Attached Lids Plastic Containers

Attached Lids Plastic Containers

Industrial Plastic Containers, Solid Walls and Botton

Industrial Plastic Containers, Solid Walls and Botton

Sand and Salt Plastic Storage Bins

Sand and Salt Plastic Storage Bins

Containers - Lids and Covers

Containers - Lids and Covers

Containers - ID and Hot Stamp

Containers - ID and Hot Stamp

Containers - Dollies

Containers - Dollies

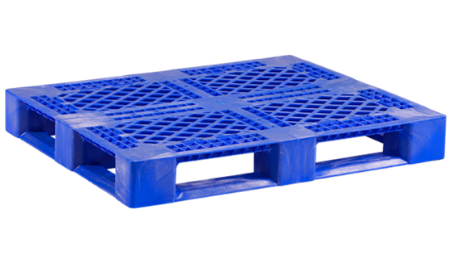

FDA Food Grade Plastic Pallets

FDA Food Grade Plastic Pallets

Industrial Plastic Pallets for Warehouse and Racking

Industrial Plastic Pallets for Warehouse and Racking

Export Plastic Pallet

Export Plastic Pallet

Display Plastic Pallets

Display Plastic Pallets

Drum Plastic Pallets

Drum Plastic Pallets

Plastic Pallet Boxes, Solid walls and Bottom

Plastic Pallet Boxes, Solid walls and Bottom

Plastic Pallet Boxes, Vented walls and Bottom

Plastic Pallet Boxes, Vented walls and Bottom

Insulated Plastic Pallet Boxes

Insulated Plastic Pallet Boxes

Tapered-wall Pallet Boxes

Tapered-wall Pallet Boxes

Removable walls Pallet Boxes

Removable walls Pallet Boxes

Pallet Boxes on Casters

Pallet Boxes on Casters

Lids - Pallet Boxes

Lids - Pallet Boxes

Pallet Box Bin Cart

Pallet Box Bin Cart

Drain Option for Pallet Boxes

Drain Option for Pallet Boxes

Custom Plastic Pallet Boxes

Custom Plastic Pallet Boxes

Food Grade Buggies / CFIA - FDA Carts

Food Grade Buggies / CFIA - FDA Carts

Industrial Poly-Box Trucks

Industrial Poly-Box Trucks

Carts Options and Accessories

Carts Options and Accessories

Leave your comment