No purchases on site

Tanks

Plastic Storage Tanks

Accessories for tanks

Tank Fittings and Accessories

Industrial Hoses

Totes & Containers

Food Grade and Industrial Containers

Pallets

Pallet Boxes

Plastic pallet boxes

Carts

Utility and service carts

- Home >

- Products >

- Plastic Storage Tanks >

- Double Wall Tanks >

- Vertical Double Wall Tank, White 1.9 sg - 48 US Gallons / 200 Liters

Print screen

Pick up

FREE PICKUP

- In person

- By your company truck

- By an independent carrier

BEFORE SHOWING UP TO PICKUP:

- Wait for our confirmation email notifying you that your order is ready

- Reply to this email specifying the day you will be picking up

- Pickup procedure and packaging information will be provided to you in the email

Shipping

- Go to the shopping cart

- Click on the button "Calculate shipping costs"

- Answer the questions

- The delivery price will be displayed

Shipping limitation ( Read here )

- Delivery to a COMMERCIAL ADDRESS ONLY

- Impossible to deliver to a residential address

Delivery in a 53-foot enclosed trailer van

- Shipping costs calculated online are for delivery in a 53-foot enclosed trailer “Dry-van”

- The customer is responsible for unloading

Equipement required on site to unlaod

- Loading dock

- Forklift with 8-foot forks

- Tractor with 8-foot forks

- If none of these equipment are available on site, delivery is not possible, you will have to pick up

Delivery option with open traile van

- Contact us if you prefer delivery by an open trailer van "Flatbed"

- The transportation cost is higher and results in an additional delivery time of 24 to 48 hours.

- To request a quote, call 450-471-2772 extension 1 or write to info@agrico-plastics.com

Shipping limitation ( Read here )

- Delivery to a COMMERCIAL ADDRESS ONLY

- Impossible to deliver to a residential address

Delivery in a 53-foot enclosed trailer van

- Shipping costs calculated online are for delivery in a 53-foot enclosed trailer “Dry-van”

- The customer is responsible for unloading

Equipement required on site to unlaod

- Loading dock

- Forklift with 6-foot forks

- Tractor with 6-foot forks

- If none of these equipment are available on site, delivery is not possible, you will have to pick up

Shipping limitation ( Read here )

- Delivery to a COMMERCIAL ADDRESS ONLY

- Impossible to deliver to a residential address

Delivery by 53-foot open trailer

- Shipping costs calculated online are for delivery in a 53-foot open “flatbed” style trailer (platform)

- The customer is responsible for unloading

Equipement required on site to unlaod

- Forklift with 8-foot forks

- Tractor with 8-foot forks

- A Boom-truck

- A lifting system

- If none of these equipment are available on site, delivery is not possible, you will have to pick up

- The 10,000 US gallon tank is only available on delivery, no pickup

Newsletter subscription

Monday - Thursday

Friday

Saturday

Sunday

8h - 12h / 13h - 16h30

8h - 12h / 13h - 15h45

Closed

Closed

Monday - Thursday

8h - 12h

13h - 17h

Friday

8h - 12h

13h - 16h

Saturday

Closed

Sunday

Closed

© All rights reserved 2026 | Agrico Plastics

Vertical Closed Top Storage Tanks

Vertical Closed Top Storage Tanks  Free Standing Horizontal Tanks

Free Standing Horizontal Tanks  Rectangular Utility Tanks

Rectangular Utility Tanks  1000 Litre IBC Tanks (Cage Tote)

1000 Litre IBC Tanks (Cage Tote)  Pick up Tanks

Pick up Tanks  Double Wall Tanks

Double Wall Tanks  Vertical Open Top Storage Tanks

Vertical Open Top Storage Tanks  Plastic Water Stock Tank

Plastic Water Stock Tank  Cone Bottom Tanks - Closed Top Plastic Tanks

Cone Bottom Tanks - Closed Top Plastic Tanks  Cone Bottom Tanks - Open Top Plastic Tanks

Cone Bottom Tanks - Open Top Plastic Tanks  Secondary containment basins

Secondary containment basins  Cage Tank Parts (IBC Tote)

Cage Tank Parts (IBC Tote)  Polypropylene and PVC Ball Valves

Polypropylene and PVC Ball Valves  Polypropylene and PVC Tank Fittings

Polypropylene and PVC Tank Fittings  Camlock Fittings

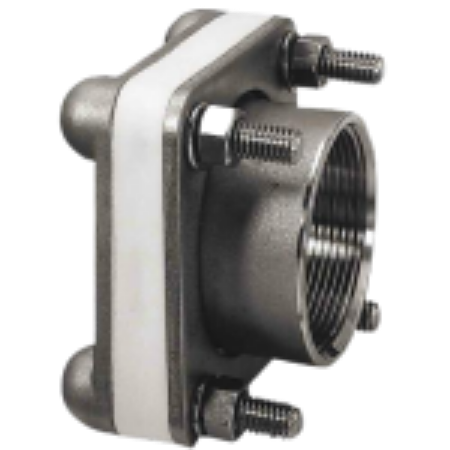

Camlock Fittings  Stainless Steel Bolted Fitting

Stainless Steel Bolted Fitting  Polypropylene Threaded Reducer Nipples

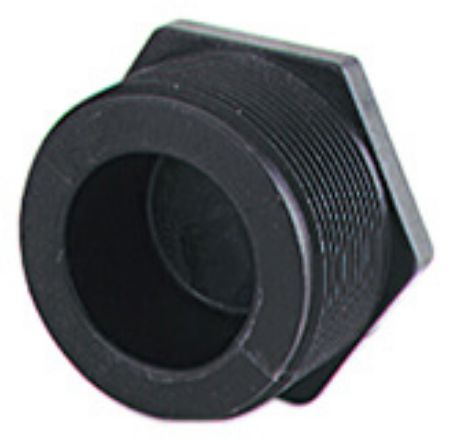

Polypropylene Threaded Reducer Nipples  Polypropylene Threaded Reducer Bushings

Polypropylene Threaded Reducer Bushings  Hose Barb Fitting Adapter

Hose Barb Fitting Adapter  Vent Caps

Vent Caps  Filter Strainer Baskets

Filter Strainer Baskets  Threaded Pipe Nipples

Threaded Pipe Nipples  Polypropylene Tee Fitting, NPT Female Thread

Polypropylene Tee Fitting, NPT Female Thread  Polypropylene Cross Fitting, NPT Female Thread

Polypropylene Cross Fitting, NPT Female Thread  Drain Plugs

Drain Plugs  Elbow fittings

Elbow fittings  PVC Adapter, NPT Male Thread to Socket End

PVC Adapter, NPT Male Thread to Socket End  Polypropylene Threaded Pipe Couplings

Polypropylene Threaded Pipe Couplings  Closed Top Tank Lids

Closed Top Tank Lids  Fire Hydrant Adapters for Quebec

Fire Hydrant Adapters for Quebec  Replacement Gasket for Bulkhead Fitting

Replacement Gasket for Bulkhead Fitting  Level Indicator

Level Indicator  Miscellaneous accessories

Miscellaneous accessories  Potable Water Hoses

Potable Water Hoses  Liquid Suction and Discharge Hoses

Liquid Suction and Discharge Hoses  Liquid Discharge Hoses

Liquid Discharge Hoses  Assembled Liquid Discharge Hoses

Assembled Liquid Discharge Hoses  Hose Clamps

Hose Clamps  Fire Hose

Fire Hose  Food Grade Containers, Solid Walls and Bottom

Food Grade Containers, Solid Walls and Bottom  Food Grade Containers, Vented Walls and Bottom

Food Grade Containers, Vented Walls and Bottom  Attached Lids Plastic Containers

Attached Lids Plastic Containers  Industrial Plastic Containers, Solid Walls and Botton

Industrial Plastic Containers, Solid Walls and Botton  Sand and Salt Plastic Storage Bins

Sand and Salt Plastic Storage Bins  Containers - Lids and Covers

Containers - Lids and Covers  Containers - ID and Hot Stamp

Containers - ID and Hot Stamp  Containers - Dollies

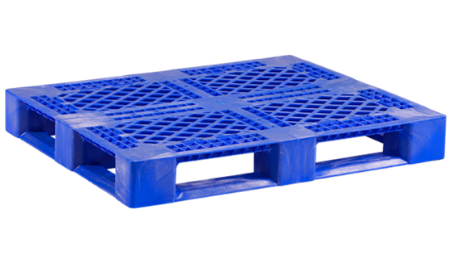

Containers - Dollies  FDA Food Grade Plastic Pallets

FDA Food Grade Plastic Pallets  Industrial Plastic Pallets for Warehouse and Racking

Industrial Plastic Pallets for Warehouse and Racking  Export Plastic Pallet

Export Plastic Pallet  Display Plastic Pallets

Display Plastic Pallets  Drum Plastic Pallets

Drum Plastic Pallets  Plastic Pallet Boxes, Solid walls and Bottom

Plastic Pallet Boxes, Solid walls and Bottom  Plastic Pallet Boxes, Vented walls and Bottom

Plastic Pallet Boxes, Vented walls and Bottom  Insulated Plastic Pallet Boxes

Insulated Plastic Pallet Boxes  Tapered-wall Pallet Boxes

Tapered-wall Pallet Boxes  Removable walls Pallet Boxes

Removable walls Pallet Boxes  Pallet Boxes on Casters

Pallet Boxes on Casters  Lids - Pallet Boxes

Lids - Pallet Boxes  Pallet Box Bin Cart

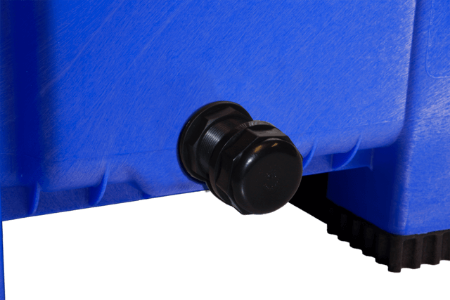

Pallet Box Bin Cart  Drain Option for Pallet Boxes

Drain Option for Pallet Boxes  Custom Plastic Pallet Boxes

Custom Plastic Pallet Boxes  Food Grade Buggies / CFIA - FDA Carts

Food Grade Buggies / CFIA - FDA Carts  Industrial Poly-Box Trucks

Industrial Poly-Box Trucks  Carts Options and Accessories

Carts Options and Accessories