No purchases on site

Delivery, installation and use of a tank

DELIVERY

- Because we do our best to deliver your goods to you in the best conditions, all the tanks received at our warehouse are pressure-washed and scrubbed with a commercial degreaser. The tanks are then stored indoors, sheltered from the weather and the sun. In order to protect them during transport, all small and medium tanks that are unstable during transport, are tied upright on a standard 48" x 48" pallet size. Larger tanks that are unstable but too high to stand on, are palletized on their side, to prevent them from rolling into the truck.

- Some tanks that are too big to be palletized, so they are shipped lying on their side, unprotected, in a 53-foot closed trailer van. These large tanks are placed on the floor of the truck, and they are pushed inside. Then, again, they are pushed out on the forks of a forklift or on an unloading dock. The tanks may arrive at the destination with stains, or scratches caused by transport.

Those tank models are: - - Vertical closed top tanks of 2500 US Gallons : # VFN40051 and VFN40052

- Vertical closed top tanks of 3000 US Gallons : # VFN40754 and VFN40755 - If this delivery method does not suit you, you can request a price for delivery with a "flat bed" (open trailer van).

This type of transport is more expensive and causes an additional delivery time of 24 to 48 hours.

Contact us to get a price: 450-471-2772 ext. 1 or by email info@agrico-plastics.com. - Before requesting a delivery, make sure you have read the delivery limitations of the tank you wish to purchase, to ensure that you have all the required equipment on site to get the tank out of the truck (such as 6 or 8 feet). By reading the limitations and conditions of delivery of the product, which can be found on our website, in the product detailed page, you ensure that they are suitable for you and that you accept them.

UNLOADING AND INSPECTION

- If the tail gate is not used during delivery, or if the tank is too big for its use, it is the customer's responsibility to take the goods out of the truck and put them on the ground. When taking your tank out of the truck, be sure to avoid any sharp objects that could damage it. Care must be taken when moving the tank with a forklift, as the forks are sharp and can easily puncture it. If your tank is equipped with a bulkhead fitting, do not place the tank on it, or let it roll on it, as it could break.

- Upon delivery, immediately inspect your merchandise for any damage that may have occurred during transit. If you notice that damage has been sustained that your tank is defective or that there is a missing part, a note must be entered on the carrier's waybill and you must notify us within 24 hours of receipt of the merchandise. Contact us, or call the customer service at 450-471-2772 Ext. 0 or write to us at info@agrico-plastics.com.

- Please note that upon receipt of your tank, the white walls of the tank may appear dirty, it is because they are stained. This is unfortunately beyond our control, because when the tanks are fabricated at the manufacturer's plant, they are stored outside. Once ready for delivery to our warehouse, they are loaded into a 53-foot closed trailer van without being palletized, so during transport between the manufacturer and our warehouse, the tanks rub against each other, as well as on the floor and the walls of the truck, and by default they get dirty. They can arrive to our plant already dirty and scratched. You can spray a degreaser on the stains and leave for 5 minutes before washing with the pressure washer.

- All tanks are made by the process of rotational moulding, and this process makes them inherit the surface characteristics of the mould. It is therefore normal that bumps and irregularities are found on your tank. These imperfections have no impact on the structural integrity of the tank.

INSTALLATION

- It is wise to install your tank in an easily accessible place to facilitate maintenance or repair if necessary.

- For safe storage and to avoid damaging the tank, it is important to prepare the surface where it will be installed. Outside, it is important to lay it on an even and compact ground such as sand, earth or fine gravel. For large tanks with a higher weight, a concrete base is recommended. All tanks stored outside should be tied down to prevent them from moving in windy conditions.

- Vertical open top tanks, vertical closed top tanks, open top conical bottom tanks and closed top conical bottom tanks can be tied down to the ground using anchors and steel cables, while horizontal tanks can be bolted to the ground or to a trailer floor using the steel bands kit which is included with the large size tanks, and it is sold separately for smaller formats. All plastic tanks that do not includes the tie-down steel bands kit can also be attached with nylon straps.

- Once the tank is filled, because of the weight of the liquid, it must be entirely supported on a solid and smooth surface in order to avoid pressure points which could pierce the base. For example, during a transport application, the tank must not exceed the floor of the trailer or the pickup box. During a storage application, it is not recommended to put a tank filled with liquid on a wooden pallet because of the gaps between the boards which cause linear pressure points.

- For safety reasons, when the tank is intended for transport, it is important to choose a tank that has been specially designed for this use. Once installed on a trailer, in the box of a pickup truck or on any other vehicle, the tank must be fixed and secured in place using straps or with steel hoops specially designed for this purpose. Steel bands hoops are mandatory on all round horizontal tanks of 725 US gallons and over, as well as on all elliptical horizontal tanks, regardless of their volume.

- Before using your tank for the first time, it is prudent to carry out a hydrostatic test, by filling it with water. This test will allow you to make sure that your tank does not have a leak. It is recommended that you fill your tank and let it sit for a minimum of 5 hours before emptying it.

- Flexible joints must be used in your piping connection to prevent damage from occurring due to natural expansions and contractions of the tanks.

- No heavy equipment should be placed or attached to the tank, it must be supported separately from the tank otherwise you could damage the tank and cause it to leak or break.

- If you must enter the tank, please follow the guidelines and regulations of the CNESST so as to respect the standards of a safe and approved environment.

USAGE TIPS:

USAERATION AND VENT

- All plastic tanks absolutely require a vent to function well and must be operated at ambient atmospheric pressure. They are not designed for pressure applications.

- A vent is necessary to allow air to enter the tank when the liquid comes out, and to let air out when it is filled. It is important to check if the tank you want to buy is equipped with a vent, which is, if there is one, always integrated directly into the lid. In case of absence, it is imperative to install an independent vent on the tank. The vent will then be installed through the tank wall, not into the lid, as it may crack. We offer vent installations or you can install it yourself.

- The vent included in the lid is perfect for filling or emptying the tank by gravity, simply open the valve and let the tank empty. When a high-flow pump is connected to the tank, or a pump with a diameter larger than the diameter of the included vent, it is recommended to add an additional vent to ensure sufficient air exchange. You will thus avoid endangering the structural integrity of the tank, either by a possible overpressure during filling, which would cause the walls to swell, or which would cause a negative pressure during emptying, which would cause the walls to collapse towards inside. Finally, the lack of air exchange could also affect the proper functioning of a pump that would be connected to the tank.

DECHEMICAL COMPATIBILITY

- You must ensure the chemical compatibility between the fluid to be stored and each of the components of the tank. It is important to check that the materials of the tank, fittings, seals and all other accessories or equipment that you wish to add to the assembly are compatible with the liquid to be contained. The different chemical compounds, their concentrations, the temperatures of use, the environment, the cleaning products, etc. are all factors that can affect tanks and their accessories differently.

- We make no warranty and accept no liability for the information provided on the chemical compatibility between your fluid and the tank and its components. It is your responsibility to confirm this information by referring either to the MSDS of the product or to any other documentation related to your product, or by informing yourself directly with your supplier of chemical products and your supplier of pumps and other equipment.

RELATIVE DENSITY (SPECIFIC GRAVITY)

- It is important to validate the relative density of the liquid to be stored in the tank so that it is lower than the maximum relative density of the tank. This way, a leak or breakage can be avoided. The relative density of a tank is always measured for use at 22°C. Relative density (DR) or specific gravity (GS) is a dimensionless quantity, as it is the ratio of density or weight. When we say that the tank has a density of 1.5 for example, this means that it can contain a liquid which has a maximum density of 1.5 at 22°C. If the density of the liquid is greater than the density of the tank, the walls of the tank will swell under the pressure of the liquid and could break. The more the temperature of a liquid increase, the more the molecules of the fluid move apart, and the more density decreases. If the temperature drops, the density of the liquid increases. Make sure you buy a tank with an adequate relative density of the liquid to be contained taking into account, the operating temperature variations.

ADDITIONAL INFORMATION

- The tanks are all made of polyethylene and can be used outdoors all year long without any problem. The operating temperature for continuous use is -40°C to 49°C (40°F to 120°F), however, it is imperative that the fluid do not freeze in the tank. Also, the tank should be protected against impacts, as much as possible, when kept at a temperature below 4°C (40°F), because plastic, like any other material, is a little more fragile when it is cooled. The resin of all tanks contains a treatment against U-V rays preventing the plastic from cracking in the sun.

- No liquid, not even water, should freeze in the tank, as the walls of the tank may crack when the ice swells. If it is stored outside during the winter, it must always be completely emptied before freezing. In case of rain, water could accumulate inside the tank due to the vented lid. It is therefore strongly recommended to leave the drain open or to open the valve so that the tank can drain all winter long.

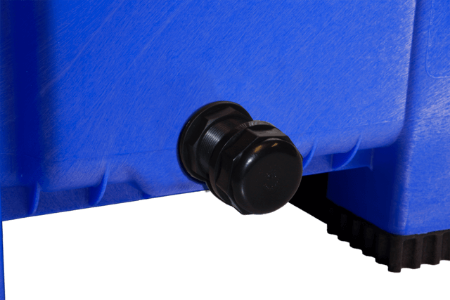

- The plastic fittings installed on a tank are only intended to be tightened with an extra ¼ turn. Overtightening the threads can cause a leak. If you notice a fitting leaking, you should first make sure the fitting is tight enough. Be aware that the compressing screw turns anticlockwise. If not, the connection must be disassembled and ensure that there is no foreign body which would prevent the sealing between the surface of the seal and the tank wall, or check if the seal is not damaged. If the fitting still leaks, it will need to be changed, the threads have probably been damaged.

Vertical Closed Top Storage Tanks

Vertical Closed Top Storage Tanks  Free Standing Horizontal Tanks

Free Standing Horizontal Tanks  Rectangular Utility Tanks

Rectangular Utility Tanks  1000 Litre IBC Tanks (Cage Tote)

1000 Litre IBC Tanks (Cage Tote)  Vertical Open Top Storage Tanks

Vertical Open Top Storage Tanks  Double Wall Tanks

Double Wall Tanks  Plastic Water Stock Tank

Plastic Water Stock Tank  Cone Bottom Tanks - Closed Top Plastic Tanks

Cone Bottom Tanks - Closed Top Plastic Tanks  Cone Bottom Tanks - Open Top Plastic Tanks

Cone Bottom Tanks - Open Top Plastic Tanks  Pick up Tanks

Pick up Tanks  Secondary containment basins

Secondary containment basins  Cage Tank Parts (IBC Tote)

Cage Tank Parts (IBC Tote)  Polypropylene and PVC Ball Valves

Polypropylene and PVC Ball Valves  Polypropylene and PVC Tank Fittings

Polypropylene and PVC Tank Fittings  Camlock Fittings

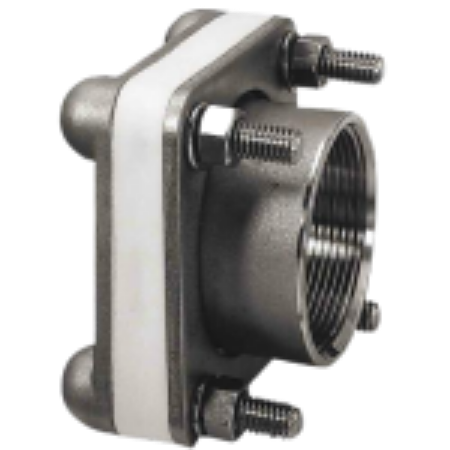

Camlock Fittings  Stainless Steel Bolted Fitting

Stainless Steel Bolted Fitting  Polypropylene Threaded Reducer Nipples

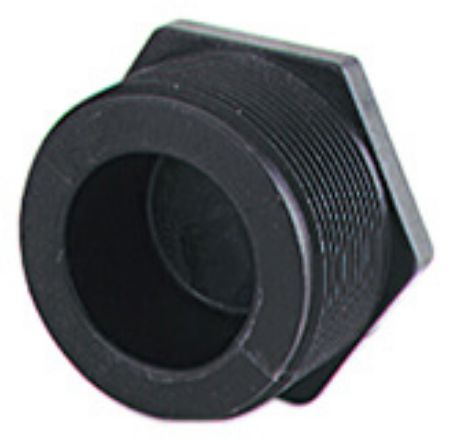

Polypropylene Threaded Reducer Nipples  Polypropylene Threaded Reducer Bushings

Polypropylene Threaded Reducer Bushings  Hose Barb Fitting Adapter

Hose Barb Fitting Adapter  Vent Caps

Vent Caps  Filter Strainer Baskets

Filter Strainer Baskets  Threaded Pipe Nipples

Threaded Pipe Nipples  Polypropylene Tee Fitting, NPT Female Thread

Polypropylene Tee Fitting, NPT Female Thread  Polypropylene Cross Fitting, NPT Female Thread

Polypropylene Cross Fitting, NPT Female Thread  Drain Plugs

Drain Plugs  Elbow fittings

Elbow fittings  PVC Adapter, NPT Male Thread to Socket End

PVC Adapter, NPT Male Thread to Socket End  Polypropylene Threaded Pipe Couplings

Polypropylene Threaded Pipe Couplings  Closed Top Tank Lids

Closed Top Tank Lids  Fire Hydrant Adapters for Quebec

Fire Hydrant Adapters for Quebec  Replacement Gasket for Bulkhead Fitting

Replacement Gasket for Bulkhead Fitting  Level Indicator

Level Indicator  Miscellaneous accessories

Miscellaneous accessories  Potable Water Hoses

Potable Water Hoses  Liquid Suction and Discharge Hoses

Liquid Suction and Discharge Hoses  Liquid Discharge Hoses

Liquid Discharge Hoses  Assembled Liquid Discharge Hoses

Assembled Liquid Discharge Hoses  Hose Clamps

Hose Clamps  Fire Hose

Fire Hose  Food Grade Containers, Solid Walls and Bottom

Food Grade Containers, Solid Walls and Bottom  Food Grade Containers, Vented Walls and Bottom

Food Grade Containers, Vented Walls and Bottom  Attached Lids Plastic Containers

Attached Lids Plastic Containers  Industrial Plastic Containers, Solid Walls and Botton

Industrial Plastic Containers, Solid Walls and Botton  Sand and Salt Plastic Storage Bins

Sand and Salt Plastic Storage Bins  Containers - Lids and Covers

Containers - Lids and Covers  Containers - ID and Hot Stamp

Containers - ID and Hot Stamp  Containers - Dollies

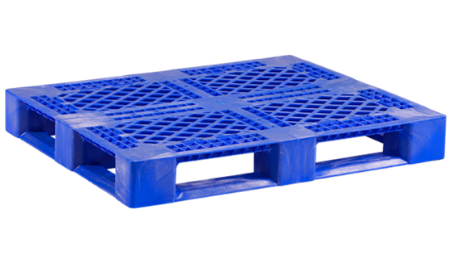

Containers - Dollies  FDA Food Grade Plastic Pallets

FDA Food Grade Plastic Pallets  Industrial Plastic Pallets for Warehouse and Racking

Industrial Plastic Pallets for Warehouse and Racking  Export Plastic Pallet

Export Plastic Pallet  Display Pallets

Display Pallets  Drum Plastic Pallets

Drum Plastic Pallets  Plastic Pallet Boxes, Solid walls and Bottom

Plastic Pallet Boxes, Solid walls and Bottom  Plastic Pallet Boxes, Vented walls and Bottom

Plastic Pallet Boxes, Vented walls and Bottom  Insulated Plastic Pallet Boxes

Insulated Plastic Pallet Boxes  Tapered-wall Pallet Boxes

Tapered-wall Pallet Boxes  Removable walls Pallet Boxes

Removable walls Pallet Boxes  Pallet Boxes on Casters

Pallet Boxes on Casters  Lids - Pallet Boxes

Lids - Pallet Boxes  Pallet Box Bin Cart

Pallet Box Bin Cart  Drain Option for Pallet Boxes

Drain Option for Pallet Boxes  Custom Plastic Pallet Boxes

Custom Plastic Pallet Boxes  Food Grade Buggies / CFIA - FDA Carts

Food Grade Buggies / CFIA - FDA Carts  Industrial Poly-Box Trucks

Industrial Poly-Box Trucks  Carts Options and Accessories

Carts Options and Accessories